Features

Applications

Beef

New South Dakota feedlot fine-tuning manure usage to gain maximum nutrient value

March 6, 2008 by Tony Kryzanowski

“Manure is finally of

great value now that the days of cheap fertilizer are done.”That

statement by South Dakota rancher, Mark Archibald, typifies the

mentality of today’s new breed of cattleman. They are keenly aware that

squandering a resource of any kind is simply poor business management.

Given the high cost of commercial fertilizers, the vast quantity of

manure generated in feedlots is gaining new interest as a valuable

natural nutrient resource and hedge against the cost of fertilizer.

“Manure is finally of great value now that the days of cheap fertilizer are done.”That statement by South Dakota rancher, Mark Archibald, typifies the mentality of today’s new breed of cattleman. They are keenly aware that squandering a resource of any kind is simply poor business management. Given the high cost of commercial fertilizers, the vast quantity of manure generated in feedlots is gaining new interest as a valuable natural nutrient resource and hedge against the cost of fertilizer.

|

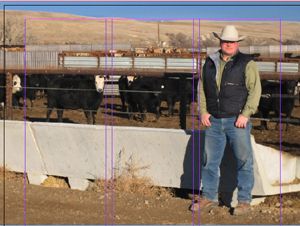

| Mark Archibald is one of three South Dakota brothers who have formed a partnership to build and manage a 6000 head feedlot. Managing manure for environmental compliance and nutrient benefit on cropland were big priorities in the feedlot design. |

The owners of Archibald Brothers Land and Cattle Company, located near the North and South Dakota state boundary near the community of Hettinger, have put a lot of thought into manure management within their new feedlot to maintain better control of its handling, storage and disposal. The business, which includes raising cattle, designing and marketing feedlot equipment, and dealing in Roto-Mix feed mixing and manure application equipment, is owned by three brothers, all of whom attended South Dakota State University with the intention of taking up a career in production agriculture. The brothers are Mark, Brad and Carter, with Mark being the oldest at 34.

They are all well aware of two issues that were a bit of a mystery to earlier generations engaged in the cattle business. These are the need for environmental compliance as well as the need for sound manure management practices for both environmental stewardship and profit.

“We realized that if we were going to be in this business, we would have to become compliant,” says Mark. “In doing so, we bit the bullet and built our feedlot so it is able to withstand a once-in-100-year event, due to our proximity to the North Grand River.”

Then there is the financial benefit of applying manure as a supplement to commercial fertilizer. “At the cost of nitrogen today, people should look at manure as a wonderful cost cutting tool in their farming operation, instead of a nuisance by-product as in the past,” says Mark. “Now, more than ever, with nitrogen costing upwards of $390 per ton, it should be seen as a necessity to clearly collect, utilize and get the most nutrient value out of every ton of manure that is produced in farm and ranch operations.”

The Archibalds know something about the cost of commercial fertilizer, given the 12,000 acres of deeded land they own, which includes 7000 acres seeded into crop.

Although the Archibald family has been ranching in the Dakotas since the Second World War, this latest generation entered a new phase of business development with the construction and expansion of cattle operations over the past four years. It started in 2003 when the brothers applied for and received a state permit to build a 6000 head feedlot. “We were always feeding cattle, but we weren’t permitted,” says Mark.

|

| The 30 foot wide spread pattern on the Archibald Land and Cattle Company’s Roto-Mix manure spreader results in less soil compaction. |

The partners started the engineering process and in 2005, they moved approximately 288,000 cubic yards of material for the new feedlot site. There were government grants available to help ensure that the feedlot would be environmentally compliant. “With the Environmental Protection Agency regulations becoming more stringent,” explains Mark, “we decided to take advantage of some Environmental Quality Initiatives Program (EQUIP) funding for both engineering and some dirt work.”

Mark, in particular, emerged from this experience having gathered a lot of knowledge about what to expect when designing and building a modern feedlot. “My best advice for people planning these feedlots is when you are ready to get started, add 20 percent to the cost,” he says, “because things happen, such as Hurricane Katrina. Make sure you have your ducks in a row for everything from your water systems to your concrete costs, to wire costs.”

A great deal of detailed engineering design was focused on the drainage system to maintain control of water collection from all aspects of the operation. It starts with the manure gathering system in the feedlot pens. The pens are structured in a herring bone design, with a 90 foot manure alley between two drovers’ alleys. The Archibalds installed their own self-standing panel products to create the drovers’ alleys. When it is time to clean the pens, the manure is scraped into the 90 foot manure alley between the drovers’ alleys, using a 14 foot wide and 42 inch tall box scraper purchased from Meyerink Farm Service located in Platte, South Dakota. It is pulled along the manure alley by using a 205 horsepower front wheel assist tractor.

“Our employees can clean our pens in a matter of three hours,” says Mark. A front-end loader stockpiles the manure and, because the pile is within the feedlot’s drainage field, the liquid leaches out, passes through a solid separator and then flows by gravity into an evaporation pond.

|

| Family members of Archibald Land and Cattle Company have been raising cattle in South Dakota since the end of the Second World War. Today, a second generation of family members is managing the operation and recently built a 6000 head feedlot. |

The ranch operates two evaporation ponds, lined with 18 inches of clay as an impermeable seal to prevent leaching into groundwater sources. One measures four acres and catches all the liquid from the cattle pens, while another measures 4.5 acres and catches water from other ranch operations and the feed storage area. Because that area of the Dakotas is so arid – receiving only about 15 inches of rain annually – the water is disposed of easily through evaporation.

The stockpiled solid manure is applied in early spring before the frost is out of the ground and with a light incorporation after the crop is removed. The ranch purchased its own 672-20 Roto-Mix vertical manure spreader so it is not reliant on custom applicators, thus giving it more flexibility on application intervals. The Archibalds purchased a properly sized used truck to transport the new spreader for a total cost of about $90,000.

Mark says there are a number of features on the Roto-Mix manure spreader that he appreciates. Firstly, the ranch was familiar with this equipment brand because they use a number Roto-Mix feed mixers in ranch operations. Secondly, he says the two vertical beaters on the back of the spreader gives him a 30 foot wide spread pattern. Also, the unloading system is belt driven and not chain driven. The result is a complete clean out during an application.

“As you are spreading in colder temperatures, sometimes sub-zero, it allows you to have a complete clean out,” says Mark. “That way, your machine won’t freeze up.”

The beaters are also hydraulically – not mechanically – driven, which means it has infinitely adjustable settings. It allows the Archibalds to custom tailor the spread pattern by either using the wing baffles at the out-feed or by adjusting the hydraulic system as they are spreading the manure. Because the manure spreader comes with a scale, Mark can also precisely calculate how much manure to apply per acre based on the nutrient quality of the manure and soil sampling.

The ranch did operate three manure spreaders mounted on Kenworth trucks previously, but they did not offer the same level of output measurement and control as with the Roto-Mix spreader. “We can custom tailor our manure applications for our ground and it allows us to be better stewards of the land,” says Mark. The wider spread pattern also results in less soil compaction.

The Archibalds were also aware they had an opportunity to design a more attractive work environment when they built their new feedlot, and that is particularly obvious in the receiving and processing barn. The ranch is a major purchaser of cattle for finishing and intends to offer custom finishing services to other cattle owners.

|

| Archibald Land and Cattle Company ensured they found a properly sized truck to transport their Roto-Mix fertilizer spreader. The feedlot applies fertilizer twice a year on some of its 12,000 acres of deeded land. |

“We built as nice a barn as we could because it allows us to recruit and retain great quality employees,” says Mark. Every feedlot is the same – you are going to be checking, feeding and processing cattle, he adds. Basically, that does not change from one feedlot to another. However, a feedlot can separate itself from its competitors and attract high quality workers by having the most efficient and user-friendly facilities possible. For example, the floor in the 70 foot by 70 foot receiving and processing barn is heated.

“With that, we wanted to have the ability to wash out our working alleyway system and cattle staging area,” says Mark. The waste material gathers in an 80 inch wide settling area. The liquid from the settling area runs into a septic system that eventually drains into one of the evaporation ponds, while a ramp system has been designed so that a skidsteer can enter the settling area and remove the solids.

Given the experience he has acquired with the construction of the

new feedlot, Mark is working with a partner to offer advice to other feedlot builders. His design suggestions are being used in a number of new feedlots, including one of the largest Angus cattle breeders in the U.S.

As far as the Archibald feedlot itself, Mark and his brothers are looking forward to the financial benefits from a more controlled application of manure on their cropland in the near future, given the soil samples they have taken, the investigation of the nutrient value in their cattle manure, and the Roto-Mix manure spreader that will do the job of ensuring that the right quantity is spread per acre for maximum value.