Variable rate application of manure is something to consider as part of

an overall focus by growers on precision farming or by custom manure

applicators for providing a value-added service to customers. One major

advantage of this method is that the same volume of manure is often

spread over a larger area.

Variable rate application of manure is something to consider as part of an overall focus by growers on precision farming or by custom manure applicators for providing a value-added service to customers. One major advantage of this method is that the same volume of manure is often spread over a larger area.

|

|

The practice of applying manure at variable rates is essentially an attempt to place the right volume of manure precisely where it is needed, based on the manure’s nutrient content and soil samples. It sounds easy in theory. It’s not so easy in practice, and is far easier to control with liquid manure than solid manure.

Variable rate manure application can vary from inexpensive, low tech, common sense methods to more expensive, high tech electronic methods featuring all sorts of off-the-shelf gadgets. Some custom applicators offer Cadillac variable rate application technology using purpose-built application equipment.

|

|

| Ag-Chem’s Falcon Virtual Terminal controller installed on its TerraGator NMS 3244 purpose-built manure applicator represents some of the most advanced technology for variable rate manure application.

|

Ag-Chem, a part of AGCO Corporation’s Application Equipment Division, is one of only a few providers of self-propelled equipment for variable rate application of manure, and offers it for solid as well as liquid waste. The company’s TerraGator NMS 9205 and TerraGator NMS 3244 units are particularly suited for the purpose. Its Nutrient Management System applies liquid or solid material up to 80 feet wide and application rates can be adjusted on the fly from one to 30 tons per acre. The system consists specifically of Ag-Chem’s Soil Geographic Information System (SGIS) desktop software to create application maps, and this information is entered into the Falcon Virtual Terminal controller. This controller controls site specific, accurate application of organic materials as directed by the map and nutrient needs of the crop.

At the farm level, some of the most accessible and affordable systems are those emanating from qualified agronomists or university research programs.

For example, the University of Illinois has developed an electronic system that allows for variable rate liquid manure application on the fly. It is portable and can be installed on either a drag hose or tanker system. Best of all, the components of the system can be acquired off the shelf, and the university can provide a general design schematic free of charge.

|

|

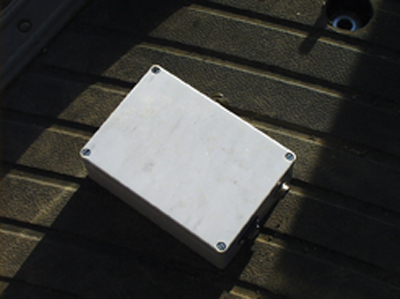

| Advances in technology, like this black box that allows various electronic components to communicate and coordinate with each other, make variable rate manure application more accessible in today’s world.

|

The system has proven effective with drag hose systems, but visiting research engineer at the University of Illinois, Matthew Robert, says there is no reason it couldn’t work on a tanker system as well, except that there is a lot more traveling involved with tankers.

It all starts with developing a proper nutrient management plan, beginning with manure sampling to ascertain the nutrient content of the liquid manure. The next step is soil sampling to determine the areas of the field where more or less manure application is required to achieve crop production targets. Growers can then input this data into a program like Farmworks, “which is just a regular fertilizer application program that we adapted to manure,” says Robert.

Software development is where Robert believes more work needs to be done in terms of creating a purpose-built application program for farm use specifically for variable rate manure application.

“Trying to use fertilizer programs is really, really hard,” he says, “and if there was a program set up for manure application, that would really get the ball rolling for all the custom applicators and producers.”

By cross-referencing the field soil sampling data with the manure nutrient data, the producer is able to calculate how many gallons of manure should be applied in specific areas of the farm. Once that data is inputted into the computer software, this produces a color-coded map indicating how many gallons of manure should be applied in specific areas of the farm. Each color represents a different volume requirement. What the producer must now determine is what speed the tractor or truck should travel and at what specific manure flow rate to achieve the proper application. The biggest challenge at this point is setting the flow rate because the flow rate from a liquid slurry will vary at times during the application, which will require a speed adjustment. Designing a quick reference chart relating flow rate to speed and keeping a copy in the cab during the application process is probably a good idea.

So how does the operator monitor all of this data during the application process? The University of Illinois has assembled a list of system hardware and how it all ties in.

|

|

| The flow meter is a critical component in the University of Illinois’ off-the-shelf variable rate manure application system.

|

The first item, at a minimum, is a laptop that can be stationed in the cab so that the operator can monitor flow rate, speed, field location, and the color-coded application prescription in real time. Robert recommends the purchase of a touch screen that connects into the laptop so that it is easier for the operator to monitor the data. The second item is a GPS unit to monitor location and speed. The third item is a flow meter. The university uses a Krohne flow meter. The fourth item is the electronic interface developed by the university that ties all the elements together and transmits the information from the GPS unit and flow meter to the laptop or touch screen.

As the operator drives across the field, he receives a constant flow reading on the monitor that, according to his chart, determines how fast he should be traveling based on his location on the field and the color code in that area. These are all visible on the computer screen. He should adjust his speed with any significant change in the flow reading, according to the chart he has prepared in advance, or when crossing from one color-coded area to another. The operator can manipulate the application rate based on speed adjustments.

Essentially, this system allows the operator to vary manure application on the fly using the flow rate and GPS color-coded map as his guide, and adjusting his speed accordingly.

“It’s very precise,” says Robert. “You can do it on a grid system very easily.” He adds that producers and custom applicators are all interested in using this method, as long as it is easy to use and that it comes at a reasonable cost. For now, he says he’s convinced the university has nailed down ease of use. Cost will vary. For example, if the operator decides not to purchase a touch screen, that represents a savings of about $2000. The total cost of the system, he says, is well under $10,000. Furthermore, after manure application is complete, all of the hardware components can be removed so that in the case of a farm tractor, it can be put to use in other areas.

Time is not always a critical element, so having the ability to make rate adjustments on the fly is not always that important. Growers in particular should balance their investment in time, effort, and cash for on-the-fly variable rate application against the speed and convenience benefits. Sometimes, if time is not a critical factor, all it takes to adopt some measure of variable rate application of manure is common sense and working with qualified farm specialists to put a well-developed nutrient management plan into action.

That’s what Agri-Trend Agrology Ltd. did recently with two of its farm customers in Manitoba. The farmers worked with Agri-Trend Geo-Coach, Warren Bills, and Agri-Coach, Denis Vermette, who helped them devise a system so that they did a better job of more precise manure application using their existing equipment, which included the use of a GPS device. With color-coded map in hand provided by Agri-Trend and the GPS unit, the growers simply applied the prescribed rate based on where they were on the field.

“Precision farming doesn’t always require the maps, the monitors and the technology,” says Bills. It is sometimes just a question of applying manure on a site-specific basis rather than as a whole.

The Manitoba farmers have achieved good results.

“We’ve noticed an improvement from five years ago,” says Elma-area farmer, Roger Giesbrecht. “There’s less lodging and more even crop maturity.”

The project started with conducting a chemical analysis of their manure sources. Then, a couple of soil samples were taken by Vermette at different depths every five acres, resulting in a color coded map that the farmers could use as reference, showing areas where manure may have been over or under applied in past years. Bills says he believes this type of field research is essential, even if farmers are working with a custom applicator offering variable rate application technology.

Now, the farmer simply adjusts his manure application volume based on where a GPS device tells him he is located on the field and cross-references that location with his color-coded map. Each grid on the map is treated like a separate field as far as manure application is concerned.

Once the farmer has the detailed map in hand, Agri-Trend recommends that he only conduct random sampling for the next five years to ensure the manure application prescription is achieving its targets. Bills says some farmers may be able to avoid another detailed soil sampling for a long time, and in some cases with the overall nutrient content evened out throughout the field, revert to a less time consuming single application rate throughout the field.

The financial payback for farmers using either the on-the-fly or spot treatment approach is that they can potentially spread the same amount of manure over more acreage, as it is being placed precisely where it is needed rather than being broadcast at a single application rate. Furthermore, there is the potential for more even crop maturity at targeted production rates.