Each year swine loss occurs due to hydrogen sulfide poisoning during

pumpout, and there have been human fatalities as well. Now a new

technology, SwineSafe™, may make those deaths a thing of the past.

Each year swine loss occurs due to hydrogen sulfide poisoning during pumpout, and there have been human fatalities as well. Now a new technology, SwineSafe™, may make those deaths a thing of the past.

|

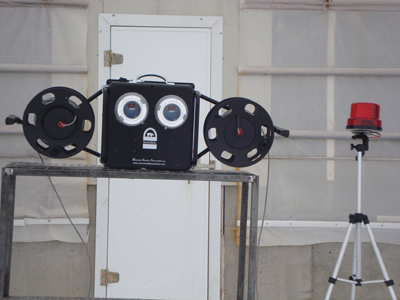

| Puck Custom Enterprises of Iowa has been working with a new system. They place the sensors in the barn, across from the agitator, when they are pumping out. Contributed photo

|

Three years ago, Ross Muhlbauer’s father lost 300 hogs from hydrogen sulfide (H2S) poisoning during a pumpout from his deep pit swine finisher. He’d used the same procedures he used for years, which had never resulted in mortalities. But now, within minutes, he’d lost approximately $45,000 in hogs.

Research and development

After the loss, Muhlbauer’s son, Ross, was determined to find a solution. Ross was a student at Iowa State University, and a research assistant to Dr. Robert Burns in the Ag Waste Management Lab. After the H2S poisoning, Ross began his own research.

|

| Each year swine loss occurs due to hydrogen sulfide poisoning during pumpout. A new technology, SwineSafe™, may make those deaths a thing of the past. Contributed photo

|

“At Iowa State we started looking at other industries that had similar problems with hydrogen sulfide, and one was the oil field industry,” says Ross. “We took some technology from that industry and started using it to monitor H2S in swine housing during pumpouts.”

After extensive research, developing and testing hydrogen sulfide detection system for use in a swine house. It worked and a paper was published on the findings.1

From there Ross took the detection units and turned them into what he calls “more of a management system,” where H2S levels could not only be detected, but alarms would sound if a H2S burst occurred. His innovative system became the SwineSafe™ Mobile (patent pending), which is available now, and the SwineSafe™ Wireless that will be available this spring through his company, Manure Safety Solutions, LLC.

“It allows swine industry workers to monitor H2S levels in swine facilities during pumpouts by using a multi-point monitoring scheme,” says Ross. “The system has alarms to notify manure applicators that dangerous levels of H2S exist in the facility so they can stop agitation and/or apply additional ventilation — without entering the facility.”

He adds, “It also has the option to integrate with the facility’s existing ventilation system and automatically add additional ventilation via fans or curtain drop in the event of deadly H2S gas release during pumpouts.

SwineSafe in action

Jeremy Puck, manager of Puck Custom Enterprises, has been working with the new system. The company employs 14 and pumped 170 million gallons last year.

Puck is pleased with the results. “We used the monitor this fall and also last spring some when the first proto-type came out,” says Puck. “When we’re pumping someone’s barn, we place the sensors in the barn, across from the agitator, and it successfully monitors the hydrogen sulfide levels.”

He adds that the system sets up in about 10 minutes. Once the sensors are in the barn, his crew run the cords out to a monitor outside, where they can easily read the parts per million (PPM) of H2S inside the barn during the pumpout.

Alarms and lights

So far Puck’s crews haven’t reached any dangerously high levels of H2S, but the system has confirmed what they always suspected — levels will rise if the gun is exposed during agitation.

|

|

| Manure Safety Solutions, LLC hopes to release the SwineSafe™ Wireless later this spring. Contributed photo

|

The detection units not only detect H2S levels but also have alarms and strobe lights that activate if an H2S burst occurs. Contributed photo

|

During the pumpout Puck says they were running around five to 10 parts per million of H2S in the air. But if there had been an H2S burst, and the H2S levels rose to more than 20 ppm, an alarm would have been set off.

“There’s both a siren and strobe light. We use the strobe light, because there’s always a person on site that’s running the pump that can see it,” says Puck. “He can shut down the agitation, turn more fans on in the barn, or he could drop a curtain.”

He adds that the learning curve is almost non-existent. “Just place your sensors where you think they should be, across from the agitator. That’s about the only learning curve there is to it.”

The monitor has an easy-to-read digital display and runs off a 12-volt battery, with a battery life of approximately 30 hours. “It can charge like a cell phone — off the cigarette lighter plugs in the truck,” says Puck. It comes standard with a A/C power wall charger.

Removing liability

Puck says that for companies like his, there’s always a gray area as to whose liability it is if any hogs are killed due to HS2 poisoning.

“This system is protection for ourselves and protection for the grower. Because nobody wins either way if the pigs die,” says Puck. “You gain a certain peace of mind monitoring — knowing that you have equipment that is accurately telling us what’s going on. Otherwise, we’re just modifying ventilation, or following protocols given us by different growers.”

Puck is also hoping that the SwineSafe™ products will lower his insurance premiums. “We’re talking to the insurance companies now. It makes sense that eliminating our risk with more monitoring equipment would bring our insurance premiums down, but we haven’t gotten a definite yes or no yet.”

Safer for people

Although SwineSafe™ was developed to keep swine from HS2 poisoning, it will help save human lives as well. From 1983 to 1990, H2S poisoning was responsible for the deaths of 24 swine workers in the Midwest and at least 15 more deaths since 1994.

Puck Custom Enterprises has always worked to ensure human life is never at risk by never allowing anyone in the barn once pumping has started. But the company doesn’t always control all the variables.

“We do a lot of sow barns where we usually work around people’s schedules,” says Puck. “Normally they work from 5 a.m. to 3 p.m. and we start pumping after they leave until morning. With a monitor, when they returned they could see if the air was clean before they came in.”

Next step – ventilation management

The SwineSafe™ Wireless will be available this spring and manure applicators will be able to purchase the control unit and add up to 32 wireless H2S sensors to their network at one site, or an unlimited number at multiple sites says Ross. “Applicators could use the same three to four sensors at every facility or each facility could have their own. And with the control unit, the applicator could read the signal from the sensors inside the swine facility. Like the mobile model, this data can then be used for alarms to alert applicators of dangerous H2S concentrations in house and/or to automatically apply more ventilation.”

Puck says he’s looking forward to the next evolution of the technology — H2S detection units that tie in directly into the barn’s ventilation system. Although the SwineSafe™ units are capable of ventilation management now, a certain amount of producer co-operation will be required to integrate fully with a facility’s ventilation management system. “That way, if there’s a burst, the ventilation would come on and pull that air out. It would be ideal for something like a farrowing barn. They are very bio-secure and we have no way to enter that barn or touch any of the controls. So we couldn’t adjust anything after the workers left.”

Another option that will soon be available is data logging. “This will allow you to log the H2S levels of your entire pump out event,” says Ross. “After it’s over, you can go back and retrieve that data and look at exactly where the H2S levels were during your whole pump out.”

Right now though, Puck is going to be strongly suggesting that his customers invest in the detection units — whether it’s the mobile or the wireless.

“It’s not an expensive investment when you look at the cost of your pigs, especially on the farrowing side,” Puck says. “Farmers put a lot of money into those sows, and for those with finishing barns, their margins right now are so slim, they can’t afford those losses.”

More tests this spring

Both Ross and Puck understand that industry won’t embrace the technology until there are more proven tests. With that in mind, Ross will demo SwineSafe™ products at a number of farms this spring.

Puck Customer Enterprises will also be using the SwineSafe™ Wireless. “We expect to have a lot more information and data after we get through this next season,” says Puck.

Ross says, until then, he’s excited about this new line of products. “We believe they will significantly increase the safety and efficiency of our customers’ operations — be they swine producers or custom manure applicators.”

(1) R.V. Muhlbauer, R.J. Swestka, R.T. Burns, H. Xin, S. Hoff, H. Li. Development and Testing of a Hydrogen Sulfide Detection System for use in Swine Housing. 2008. Proceedings: 2008 ASABE Annual International Meeting. June 29-July 2, 2008.