Features

Anaerobic Digestion

Applications

Business/Policy

Dairy

Energy

Energy Production

Profiles

Consumers going green

Biogas-generated power from four Michigan dairies chosen to help utility meet green energy goal

May 8, 2015 by Tony Kryzanowski

The anaerobic digester at the Green Meadow Farms dairy was built in cooperation with Michigan State University and generates 800 kilowatts of power that is now sold through a power purchase agreement to Consumers Energy. Photo by Contributed

Four Michigan dairies have been chosen to supply renewable power to Consumers Energy, using biogas fuel harvested from anaerobic digestion of their manure. While three of the farms already have digesters installed, one is spending more than $8 million to install a new manure processing, biogas production and renewable power facility.

Michigan passed a law in 2008 requiring Consumers Energy, Michigan’s largest, privately owned power utility, to generate 10 percent of its power from renewable sources by the end of this year. To meet that goal, it launched it Experimental Advanced Renewables Program (EARP) in 2010, with the goal of purchasing renewable energy from a variety of sources.

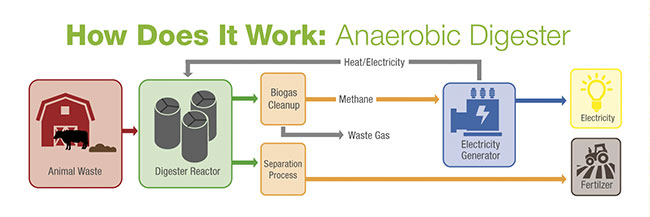

Anaerobic digestion is a biological process where raw manure is fed into large concrete tanks and mixed with water in an oxygen-free environment. The manure is mixed for a specified number of days at a set temperature, allowing bacteria to break down the raw material, producing methane gas that rises in the tank, which is then harvested and burned as fuel in an engine that drives a power turbine.

Beaver Creek Farms, located new Coopersville, Mich., has chosen Sustainable Partners LLC (Spart) to build an anaerobic digester and biogas power system at its over 3,000 head dairy. The installation will produce 1.4 megawatts (MWs) of power.

“We have been interested in a digester for a long time,” says Bill Henke, Beaver Creek Farms owner. “It just finally made sense when Consumers opened up the EARP with a reasonable price for purchasing power.”

The dairy generates about 100,000 gallons of manure per day.

Michigan has about 2,650 dairies. Greg Northrup, Spart’s co-owner, says that, “every one of the 100 largest dairies in Michigan could be producing power.” However, the challenge to this point seems to have been the rate that power utilities have been willing to pay for the generation of that power.

In addition to dairy manure, which Northrup says will supply the digester on the Beaver Creek Farms location with, “a constant supply of feedstock which allows the plant to produce energy 24/7, 365 days a year,” the digester will also process fats, oils and greases from restaurant grease traps.

“Biogas projects also generate valuable renewable energy credits and carbon credits which can be used by third parties to achieve regulatory compliance,” says Northrup.

Henke says the anaerobic digester on Beaver Creek Farms will generate extra cash and help with manure management.

“We reduce our volume of manure since some of it is consumed in the digester,” he says, “and there are other things like the potential use of the solid output of the digester to bed cows and just the general reduction in the hassles of manure management.”

Other benefits to sending the manure to the digester are that the farm retains the nutrients for land application, “but loses the odor,” Henke says.

He and Spart plan to partner in a new company that will own and operate the biogas and power production facility and intend to break ground on the Beaver Creek Farms digester in June. They plan to apply for a $500,000 grant available for these types of projects through the United States Department of Agriculture. Participants in EARP have two years from their notice to construct their system and begin generating electricity to achieve their Commercial Operation Date (COD). Once that is reached, they can begin to make money from the power they generate. Of the 1.4 MWs produced at Beaver Creek, 400 kWs will be used by the dairy and to operate the digester system, while 1 MW will be sold to Consumers Energy.

“The addition of anaerobic digestion brings more diversity to our existing renewable energy supply from wind, solar, biomass and hydroelectric dams,” says Timothy Sparks, Consumers Energy’s vice-president of energy supply operations.

Brian Wheeler, Consumers Energy spokesman, says what EARP offers the four selected dairies is greater certainty of income by locking in the price they will receive over the life of each power purchase agreement (PPA), adding that the company decided to engage with the agriculture industry because it is the second largest industry in Michigan with plenty of opportunity for biogas production build out. A total 2.6 MWs will be purchased from the dairy farms under Consumers Energy’s EARP. The power generated is estimated to be enough to supply 2,800 homes.

Besides Beaver Creek Farms, the other three dairies chosen to participate in EARP were Brook View Dairy in Freeport, Green Meadow Farms Inc. in Elsie, and Scenic View Dairy in Fenneville. Some already have experience selling power generated by their anaerobic digesters to the power company.

Consumers Energy offered program participants two rate options when applying for the program. The first is what the company calls a ‘levelized’ rate that will pay $86 per MW/hour for the full 20-year term of the PPA it has with the dairies. The second option is a rate payment schedule that will allow participants to specify the term of their PPA to be between 10 and 20 years. Three of the dairies opted for a 20-year PPA, and one a 10 year PPA.

Consumers Energy officials say the company developed its EARP in consultation with Michigan State University and the agriculture community. The university helped with the dairy selection process and it provided resources to help project developers perform an initial screening of potential projects to determine if further investigation was warranted. This was accomplished with the use of two evaluation tools. One was the Michigan Waste Biomass Inventory, which helped developers locate potential feedstocks for their proposed digesters, and the second was the Anaerobic Digestion Development Iterative Tool (ADDIT), which assisted in the screening of different digester parameters.

The Green Meadow Farms dairy in Elsie is one of the largest dairy farms in Michigan. It’s owned by Velmar and Margaret Green, and their children: son, Craig, and his wife, Darcy, and daughter. Margie. They manage 9,500 head of cattle and farm 6,500 acres, and have a close relationship with Michigan State University. Their dairy is home to the university’s Training Center for Dairy Professionals.

“Before, we were selling electricity to Consumers Energy off of the board price,” says Darcy Green. “This new program sets the price at a higher, more stable level.”

The dairy has developed a complex system for treating manure that starts with using six MacLanahan sand-manure separators to separate the sand bedding from the raw manure collected from barns on two farms. After separation, the manure is either land injected or treated with ferric chloride and a polymer. The ferric chloride neutralizes the manure’s pH and the polymer binds the nutrients together. A belt filter press separates the solids from the liquids from this mixture, resulting in two products – clear water that is recycled to flush parlor floors and to separate sand from the manure, and a fibre cake that is land applied as a fertilizer or composted by a third party company called Morgan Composting.

The dairy added a methane digester in 2006 through a project with Michigan State University’s Department of BioSystems & Agricultural Engineering. It was part of a study investigating how to create methane at a dairy that uses sand bedding. All the raw manure previously destined for the treatment plant is now processed through the anaerobic digester before it is sent to the treatment plant. According to the dairy, this reduces the amount of ferric chloride added to the solid by-product.

The Green Meadow Farms anaerobic digester consists of three tanks, each capable of holding 900,000 gallons of manure. The biogas produced by the digester is burned in a Caterpillar V16 engine that powers a generator capable of producing 800 kW per hour.

Scenic View Dairy and Brook View Dairy are sister dairies run by various members of the Geerlings family. Both are located about an hour from Grand Rapids, Mich.

Scenic View Dairy milks about 1,900 cows with an additional 1,500 dry cows and heifers. Its $3.2 million anaerobic digester consists of a three-tank system, which began producing power in 2006. The dairy generates about 28 million gallons of manure per year.

Brook View Dairy milks 2,200 cows, with an additional 1,000 dry cows and heifers. Its anaerobic digester was installed in 2008, consisting of three digester tanks, each with a holding capacity of 930,000 gallons. The dairy generates about 24 million gallons of manure per year.

In addition to dairy and heifer manure, the digesters also process syrup stillage, waste produce, fats, oils and greases. The biogas generated by the digester at Brook View is burned in two Caterpillar G3516 co-generation engines, each capable of generating 800 kWs per hour.

The spent digestate from the tanks is processed through FAN separators, creating a liquid and a solid stream. The nutrient-rich liquids are land applied as fertilizer and the pathogen-free solid stream is used for animal beddings both on and off the dairy site.

Andy Austin, anaerobic digester manager for both dairies, says they were already marketing their power under contract to Consumers Energy at about the same rate as is being offered under EARP. What participation in EARP provides them is a guaranteed market for their power for the next 20 years. Having that market was a concern as their PPA with Consumers Energy was expiring at the end of this year.

Both the Scenic View and Brook View dairies also sell carbon offsets generated from diverting their farm manure through the digestion process and creating biogas to generate renewable power rather than simply land applying it. This has created another income stream for the dairies, which has helped to offset the cost of the digester installations.