Acme Engineering &

Manufacturing Corporation has grown to become a world leader in the

design, manufacturing and distribution of fans, blowers and ventilation

equipment.

Acme Engineering

|

Acme Engineering & Manufacturing Corporation has grown to become a world leader in the design, manufacturing and distribution of fans, blowers and ventilation equipment. The company has become an industry leader in providing customers with a wide range of selections for every possible ventilation requirement.

Acme manufactures one of the broadest lines of air moving equipment in the industry at its plant location in Oklahoma. With over 350,000 square feet of space, the manufacturing facility is equipped with modern computer assisted machinery and automated tooling to produce components to tight tolerances so that final assembly operates at the designed performances. The Acme Research and Development Center houses three wind tunnels, electronic sound measuring equipment, a reverberant sound room, Cad/Cam systems, finite element analysis capabilities, and stress and vibration analyzers. Endurance testing over time insures operational reliability by assuring that motors and components perform under actual load conditions.

www.acmeag.com

American Coolair

|

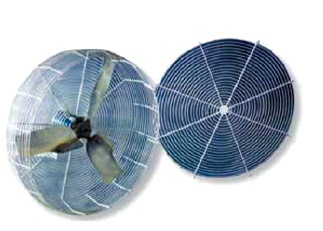

American Coolair’s NBF fans are built to give years of heavy-duty service. Their rugged, belt-driven construction operates in any position, they have permanently lubricated ball bearings and they are available with single- and two-speed enclosed motors. The painted finish of the NBF fan protects against corrosion.

Quality materials and precise engineering techniques in wheel assembly construction assure years of quiet, trouble-free service, the company says. The NBF is an economical option in terms of cubic feet of air per minute per dollar invested.

www.coolair.com

Better Air Systems

|

Better Air Systems recommends a negative pressure system for evenly controlled, draft free, year round ventilation. Exhaust fans create negative pressure, removing moist contaminated air. Fresh air is pulled in through carefully positioned and controlled inlets, mixed, re-circulated and, if necessary, heated for precise moisture and temperature control. A consistent and comfortable environment supports healthy and productive animals.

The key to better negative air-pressure ventilation systems is the adequate removal of moist contaminated air by exhaust fans. The company’s fans and accessories are designed to meet a wide spectrum of ventilation needs and requirements.

The key benefits of the company’s air exhaust fans include: automatic open and close shutters; size range of 10” to 50” diameter; three choices of motors; and a UV treated polyethylene house.

The housing is UV treated polyethylene, sturdy and corrosion free. The slanted design of the company’s wall-mount exhaust fans projects the fans 12” outside of barn. Condensation flows down and away from the barn, keeping walls clean and dry. The inside mounting is flush, eliminating obstructions along walkways. The aerodynamic housing funnel encourages free air flow.

www.betterair.ca

Chore-Time

Comfortable birds are healthier and produce better, and Chore-Time’s air systems can help. The company says it has the products growers need to “turbo-charge” their environmental controls.

The company’s products feature fiberglass housings and cast-aluminum blades, superior air flow and efficiency. The one-piece cone on the fans improves air flow up to 10 percent, and the cone and grill unit removes easily for cleaning. Corrosion-resistant plastic shutters are also available.

www.ctbinc.com

SKOV

|

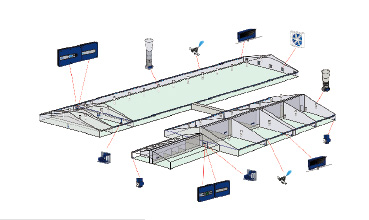

SKOV is a leading producer of accurate equipment for climate control used for animal production. SKOV is a system supplier and makes great efforts to develop solutions in which the components are optimized in relation to the system. Complete systems from SKOV have been providing the perfect climate for over 35 years—ensuring optimal health, growth and the best possible productivity.

The LPV—low power ventilation—system is a classic negative pressure system. Fresh air is taken into the house via wall or ceiling inlets, and the air is let out through chimneys in the roof.

The SKOV inlets provide an optimum airflow at all ventilation levels. At minimum ventilation, the air is directed upwards to the ceiling of the building. At maximum opening, the air moves across the animals creating airflow, and thus creating a cooling effect through air velocity.

During hot periods, an efficient cooling system is conducive to the well-being of the animals and productivity. Using the high-pressure cooling, the air is provided with finely atomized water vapor, which cools the air inside the building.

The exhaust is carried out by chimneys. The aerodynamic shape of the SKOV chimney offers a high air performance at low energy consumption, discharging the air high into the sky.

The SKOV climate computer ensures that all components in the ventilation system work together. Through secure Internet connections, the climate conditions in the building can be analyzed.

www.skov.com

Roll Seal Green

Roll Seal Green’s Mega Flow and Funnel Flow fans round out a broad and complete energy efficient line in the industry.

Mega Flow fans set the standard in performance, quality and longevity, says the company. Mega Flow fans have been designed from the ground up to insure the ultimate performance from a galvanized fan. They are available in belt or direct drive models.

Funnel Flow fans are built for years of trouble-free performance, even in the most rugged conditions. Funnel Flow fans feature fiberglass housing, precision, and one-time balancing of the propellers which insures optimum efficiency. They are also available in belt or direct drive models.

www.rollseal.net

Del Air

|

The CV4000 double-sided ceiling air inlet is the new inlet in Del Air’s CV series line. Being a double-sided inlet, it is designed to supply the correct air pattern for facilities. Designed for today’s larger facilities, the inlet will allow a large amount of air into the building where needed.

The all-plastic design allows for long product life and will allow the unit to stand up to pressure washing and virtually anything else thrown at it. The inlets will allow fresh air to be supplied throughout the attic, allowing managers to easily direct fresh air to essential areas.

This inlet can only be controlled via actuator or winch, but ease of installation and hook-up allows for virtually no additional maintenance to the inlet. Customers are invited to contact their Del-Air rep about the insulated version of this inlet.

www.del-air.com

J&D Manufacturing

|

J&D Manufacturing, Inc offers a full line of products to meet ventilation or cooling needs. With years of experience, the company’s staff can help design a system to meet an operation’s exact needs. The company’s systems are used on a variety of livestock installations, from dairy farms and hog installations to poultry installations.

Operations can reduce heat stress and resultant production loss by utilizing natural ventilation designs. These practices can further optimize systems with automated ventilation systems. Exhaust fans can be combined with intake shutters and environmental controls to replenish, cool, and refresh the air inside dairy barns.

Depending on the location and building design, air circulation may be another vital component of an environmental control system. Circulation fans can be mounted to rafters, posts, columns, or hung from the ceiling to create a horizontal airflow to mix, temper, and refresh all areas of the building.

www.jdmfg.com

Norbco

|

Norbco is now manufacturing a proprietary line of circulation fans including the 36” Norbco circulator, 52” portable fan, and the Magnum 52 and Magnum 60 panel fans.

The Magnum 52 has proven to be an ideal fan for freestall barns, providing high air velocity for effective cow cooling. Powered by a high efficiency 1 hp motor (single- or three-phase) it produces 31,200 cfm at 460 rpm, all at a low noise level. A rotary belt tensioner is standard, assuring original design performance. A unique Norbco designed motor, blade and fan mounting assembly attaches directly to the heavy gauge galvanized venturi panel providing a durable, compact unit. Norbco also manufactures a complementary line of mounting brackets for attaching the fans to headlock posts or to steel or wood structural columns. The resulting combination provides 100 percent adjustability to maximize airflow over the cows.

Norbco manufactures a complete line of rugged, heavy duty barn equipment designed for the commercial dairyman.

www.norbco.com

PORC Systems

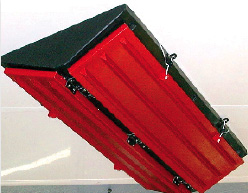

Odor reduction with the system designed by PORC Systems LLC involves three basic principles: physical entrapment, water chemistry and microbial activity. PORC (Pork Odor Reducing Control) utilizes all three principles in the company’s design strategies. Cost, efficiency, ease of operation and public effectiveness are also essential contributing factors of a successful site specific odor reducing technology. PORC Systems’ odor cell technologies are adaptable to most existing ventilation systems.

Utilizing the company’s recommended filtering medium, pine bark, a majority of particulates are physically entrapped reducing the transmission distance of odor.

The odor absorption qualities of a properly hydrated P-8 filter creates an environment in which hydrogen sulfide, ammonia and other unwanted gases can be reduced. To maximize the hold time within the filtering microbial panels, wing diverters or odor cells can be designed to meet specific site requirements.

The organic composition of the company’s properly hydrated filtering medium creates an environment that promotes extensive microbial activity. This activity not only reduces particulate build-up, extending the life of the bark, but also aids in the reduction of gaseous emissions. Balancing air flow, pH and moisture are crucial to a properly maintained odor filter.

The odor filters are designed to be user friendly. By removing the top panels, inspection of the filtering bark can be done routinely. Remove three wing nuts, and the P-8 odor filter becomes four individual filtering panels that can be easily moved, allowing access to the pit during manure application. A rock base pad is recommended when installing P-8 filters.

PORC Systems: (319) 624-7176

Prairie Pride

|

Prairie Pride was the first company in North America to manufacture polyethylene fan housings, says the company, achieving highly durable, highly cleanable fans with the best features for barn applications. Since then, Prairie Pride has gone on to develop extensive lines of wall fans, roof exhaust fans and air inlets that meet the many different ventilation requirements in North America.

The company has seen a trend in power ventilated barns toward roof exhaust fans.

Roof exhaust fans provide the opportunity to place the fan location where required, drawing out contaminated air as close to the source as possible. This is extremely critical in cold climate areas where airflow is low.

Roof exhaust also takes advantage of the vacuum effect created when the wind travels over the top of the roof exhaust, creating a suction drawing air through the roof exhaust and highly improving its efficiencies. In fact, the company finds that in the winter they must damper the roof exhausts to keep too much air from being drawn out.

Prairie Pride has a complete line of modular fresh air inlets to allow for optimum placement and bring fresh air into the barn to provide the freshest air right to the animals or birds. This is now typically done through the ceiling for best positioning.

Prairie Pride controls its ventilation systems with Phason controls which they have found to be the most user-friendly controls on the market. The philosophy that Prairie Pride uses in its ventilation systems is that the barn owner or manager makes the ventilation system work successfully, so the controller must be user-friendly and easy to understand and program.

One of the most common controls being used from the Phason line in Prairie Pride’s ventilation is the SUPRA, which provides ventilation control as well as the ability to monitor humidity and water consumption.

www.prairie-pride.com

Phason

Phason’s Evaporative Cooling Control is designed to automatically control sprinkler solenoids, water pumps, and single-speed fans for direct or indirect evaporative cooling systems.

Designed with versatility and usability in mind, the Evaporative Cooling Control (model ECC-1) has two main modes of operation: “Soaker Mode” for direct evaporative cooling or “Mister/Fogger Mode” for indirect cooling.

The ECC-1 monitors temperatures and efficiently and effectively controls evaporative cooling cycles according to user-programmed settings. With optional humidity monitoring, users can expand the control’s capabilities even more.

The ECC-1 evaporative cooling control is ideal for many applications, including dairy, swine and poultry.

www.phason.ca

Schaefer

|

Schaefer Ventilation Equipment’s goal is to provide the end user with a ventilation solution. The company does this in a number of ways, including product innovation. Through research and customer feedback, the company has developed an extensive line of innovative products to fill customer needs. Recent innovations such as the company’s panel fan, misting, cooling and heating products along with other core products provide solutions for almost any customer environment situation.

The company’s 36” and 48” high velocity air circulation fans feature heavy-duty, galvanized construction, with high-efficiency orifice/venture. They are engineered for peak performance and quiet operation. Hanging mounts are available. They have a totally enclosed motor, thermally protected and cast pillow-block.

www.schaeferfan.com

Val-Co

The company’s HyperMAX fiberglass belt drive fans in 36”, 48” or 50” are said to offer high performance and maximum value.

The HyperMAX motor mount and drive assembly utilizes a rugged box frame design to improve performance, efficiency, increase motor life and provide quiet operation. An auto belt tensioner reduces maintenance and units can come standard with the auto tensioner or reverse drive. They feature energy efficient, waterproof motors with sealed ball bearings and thermal overload protection, and are manufactured to Val-Co’s exacting specifications.

Motor options include single- or three-phase motors in 50 Hz or 60 Hz and various operating voltages. The fans have a unique four-point, galvanized or stainless steel motor mount design that provides minimum air restriction and vibration-free performance.

The computer designed orifice-blade-cone-motor combination assures optimum use of the motor power curve while reducing starting and running amps. Blade options include rust proof stainless steel, cast aluminum or galvanized. Matching blades and energy-efficient motors provide maximum CFM/watt of electrical power.

www.valcompanies.com

BSM Agri

BSM Agri Ltd manufactures a diverse line of livestock housing and ventilation equipment for the worldwide marketplace. The company is based upon a strong reputation for building quality products for the modern farming operation.

Whether it is products for dairy, hog, poultry, beef, or other types of livestock operation, BSM Agri Ltd has the dedication and experience to make the customer’s next building or renovation project a success.

Years of experience in the design and manufacture of livestock housing equipment ensure quality, cost effective products with proven dependability and performance, the company says. The latest technology, equipment and computer programs are always utilized, resulting in designs and products that keep BSM on the forefront of new developments within the industry.

The recent merger of Canarm Agricultural Products and BSM Agri has resulted in a much stronger ag sales group with an extensive line of livestock equipment, as well as the company’s innovative high quality environmental control products and systems.

www.bsmagri.com