Features

Reaping the benefits

Nutrient and manure management planning policies should accommodate advancing precision agriculture technologies.

June 5, 2020 by Robert Meinen

Agitation will help to suspend and remove solids from a manure storage. While the manure nutrient content delivered to the field is expected to be more homogenized after agitation, load-to-load variation will surely occur. Photo courtesy of Robert Meinen.

Agitation will help to suspend and remove solids from a manure storage. While the manure nutrient content delivered to the field is expected to be more homogenized after agitation, load-to-load variation will surely occur. Photo courtesy of Robert Meinen. The benefits of in-field, on-the-go manure analysis shouldn’t be overlooked. Real-time manure nutrient measurement can be used to adjust manure application rates based on expected crop production yields. This up-and-coming technology, along with other ever-evolving precision agriculture tools, can have a positive influence on agronomic, economic, and environmental goals.

A case for modern technology

Modern technology is continually advancing. Manure handling equipment and software can allow immediate in-field nutrient assessment as manure is being applied. When coupled with contemporary computer-driven variable-rate application equipment, in-field analysis may become the gold standard of matching manure nutrient content to in-field crop nutrient uptake. These systems use integrated geographic information systems (GIS) to pair spatial variations of harvest yield history with variations in manure nutrient content. Manure application rates are automatically adjusted to most efficiently match expected crop uptake needs in real-time. On the farm, this technology can provide agronomic and economic efficiencies and many environmental benefits.

But while technology has advanced, industry uptake is lagging behind. Current policies can act as a barrier to adoption of these kinds of precision agriculture technologies because manure analysis and corresponding manure application rates must be determined prior to application, using data from previous seasons. Agencies charged with protecting the environment against agricultural nutrient losses need to encourage change through legislation, regulation, and policy adaptation. This will allow integration of these systems into nutrient and manure management planning and practices.

There are ways to verify equipment and system calibration. Reasonable on-farm testing, record-keeping, and review can be used in concurrence with laboratory analysis to prove that nutrient misuse does not occur. Maximum nutrient or volume application rate parameters can be added to the computerized and mechanical components of these systems to prevent over-application. These integrated systems can automatically produce accurate records that reflect field activities.

Manure sampling inaccuracy is currently acceptable

Current manure sampling protocols come with inherent challenges. Manure analysis is a critical component of two goals of nutrient management planning. First, analysis identifies nitrogen (N), phosphorus (P), and potassium (K) contents in manure that are used in conjunction with projected crop yield and soil analysis data to ensure efficient agronomic nutrient utilization. This information is then used to determine manure application rates meant to optimize nutrient utilization to assist farm-level agronomic and economic objectives.

Secondly, when meeting the goal above, analysis aids in protection of the environment from the inadvertent release of nitrogen and phosphorus when manure is applied to farm lands. Planning based on manure analysis also encourages efficient use of supplemental commercial fertilizers.

Current manure sampling recommendations come with inherent inaccuracy, which is commonly seen as acceptable. Collecting the proper number of samples can lead to measurements that are within plus/minus 10 percent accuracy of average content for solid manure. However, attaining such accuracy may require significant investment in time and money (Miller et al., 2019) and may not be practical at the farm level.

For liquid manures, Dou et al. (2001) noted that if thorough agitation occurred, five samples could be composited to accurately represent average manure storage content for N and P, but the recommendation increases to at least 40 samples in the absence of agitation. Davis et al. (2002) found that for solid manure, 24, 27, and 21 samples were needed to achieve this goal for total N, P, and K, respectively, but more than 100 samples were needed for ammonium and nitrate. This level of sampling intensity rarely – if ever – occurs in the field.

To meet nutrient and manure planning requirements, manure samples are usually collected well ahead of time; often, this sampling occurs 12 months before the application season for which the rate is determined. It is common to use historic samples or averages of samples from previous years to determine application rates, but this can introduce error into a planning process where final nutrient application preciseness is needed to meet program goals. Even if the sensing accuracy of this up-and-coming field technology was plus/minus 20 percent, it would still be more accurate than many current practices. When coupled with variable rate application based on historic crop yield and localized soil productivity, the benefits become greater.

Computer programming that integrates with application tools is available to assist in manure application rates based on both N and P. Furthermore, this technology can determine both total and ammonia N content, meaning N-based application rates can be refined in real-time based on application method and N availability factors.

Additional benefits of in-field, real-time manure application rate determination

When coupled with harvest yield data, this technology can allow variable rate manure nutrient placement based on expected yield of the upcoming crop. In this manner, manure application moves from a pre-planned per acre calculation to a real-time per square meter calculation based on the actual manure nutrient content of the material being applied.

Whether the results of implementing this technology mean that the total volume of applied manure across the acreage of a given field is equal to, more, or less than current planning application rates, careful and precise placement of manure nutrients should lead to improved crop uptake efficiencies. This lowers the risk of loss to the environment.

In low-yielding areas of a field, lower manure application rates mean manure nutrients are not supplied in excess of expected crop uptake on a meso-level. Low-yielding areas in any given field, such as soil-compacted headlands, are often those near an environmentally sensitive field edge. Conservative application rates in these areas may directly reduce environmental risk of nutrient transport.

Manure variation within a storage

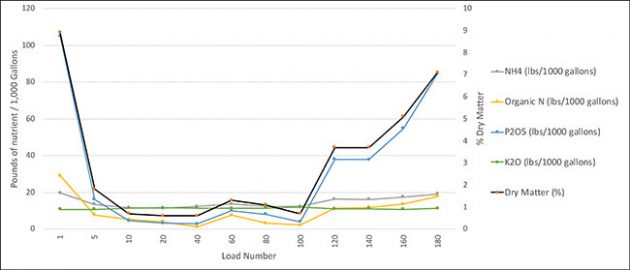

Figure 1 shows nutrient and dry matter concentrations from an unagitated liquid manure storage at a Pennsylvania sow farm. This unpublished data (Meinen, 2011) demonstrates that higher levels of dry matter contained higher levels of P in this storage. During this unloading process, manure was pumped from the very bottom of the storage where the initial loads were very thick (loads one to five) before the liquid portions could easily flow over remaining solids and into the pipe. The slight increase of dry matter at load 60 was due to settling during overnight inactivity. After the very liquid portion was removed, the stratified thicker slurry manure moved to the pipe beginning around load 120. Investigation of the data at this storage estimated that 39 percent of total P was found in just 12 percent of the manure volume in the initial (loads 1-5) and final (loads 161-180) loads of manure, while just 13 percent of P was found in 58 percent of the manure volume of the loads with lowest dry matter content (loads five to 100). Collection of samples during load 20 and load 160, for example, would generate application rates that were very different.

Figure 1 Nutrient content (pounds per 1,000 gallons) and dry matter content (%) of manure sampled from an outdoor manure storage basin at a sow farm as manure spreaders were loaded for transport to land application locations. Total N is not shown to eliminate clutter from the graph. (Meinen, 2011).

It is apparent in this scenario that real-time field analysis would lead to efficiency gains, as compared to traditional sampling methods that assign a single P value to represent the entire manure volume (more than 1,000,000 gallons).

Final thoughts

In-field, real-time manure sampling highlights the need for adaptable nutrient and manure management policies that respond to precision agricultural technologies. As time moves forward, these technologies will continue to make strides in accuracy. Policies should flexibly allow for such technological advancements to avoid adoption barriers and promote the use of beneficial advanced integrated technologies. Working together, this will progress agronomic, economic, and environmental goals.

Robert Meinen is a senior extension associate with the Penn State Department of Animal Science.