Vaughan Co, Inc is the first and

only company in the world entirely devoted to the manufacture of the

chopper pump, according to the company.

Vaughan Co

|

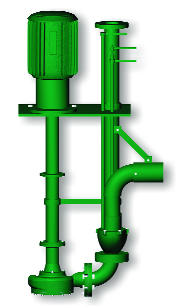

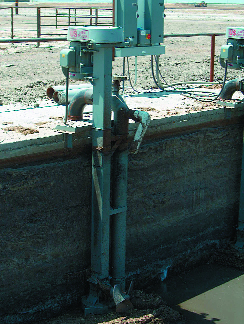

Vaughan Co, Inc is the first and only company in the world entirely devoted to the manufacture of the chopper pump, according to the company. This chopper pump was originally invented by Jim Vaughan over 45 years ago for dairy manure handling in the Chehalis Valley of Washington State. With 32 patents and over 20,000 units successfully installed worldwide, Vaughan chopper pumps are now utilized by all industries worldwide to handle the most difficult solids pumping applications. In the dairy industry, Vaughan chopper pumps are primarily used for manure pits and lagoons, and are also available with recirculation nozzles for mixing.

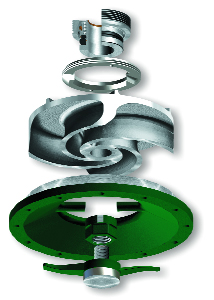

Vaughan chopper pumps are designed for severe-duty application, with all cast and heat treated wear components including the impeller, cutter bar, upper cutter and cutter nut. The shaft system includes oil bath lubricated ball bearings with a heavy-duty cartridge mechanical seal designed and built by Vaughan. Pump volute and bearing frame are also cast in ductile iron for long life expectancy.

Vaughan chopper pumps are available in the following configurations: vertical wet well, cantilever, vertical dry pit, horizontal end suction, electric submersible, hydraulic submersible, vertical recirculator, submersible recirculator and self-primer. Sizes range from 3” to 12” discharge, with flows of 50 to 8,000 gpm and heads up to 280’. Materials of construction are stocked in either ductile iron and steel, 316 stainless steel and CD4MCu heat treated stainless steel.

Vaughan maintains a multi-million dollar parts inventory of all production and wear parts for expedited delivery of both pumps and parts, including many custom orders. All Vaughan chopper pumps are guaranteed in writing for performance and continuous operation without clogging.

www.chopperpumps.com

ITT Flygt

|

The F-3000 series of submersible chopper pumps from ITT Flygt Corporation are said to be among the toughest and most reliable pumps for handling animal waste, dairy and farm wash-down, poultry wastewater sumps and fibrous waste applications. Pumps are available in 4” and 6” models, with motors ranging from two hp through 20 hp. The unique back-swept impeller chops solids 175 times per second, turning material into small easy-to-pump pieces.

www.flygt ron.skinner@itt.com

Bauer

|

The powerful chopper of Bauer’s Magnum pumps can handle up to 12 percent solids. The pumps feature a radial housing and their large-dimensioned pumping channel ensures unobstructed delivery of viscous liquids. The rinsing connection is designed for flushing the seal chamber with clean water to keep fibers and solids from settling. The result is higher operational safety and longer pump life. The pumps have compact spur gearing with case-hardened helical gearing running in an oil-bath.

With the cutting flange, the high-grade casting and hardened cutting edges guarantee long life. It provides excellent cutting performance on cutting edges and impeller, says the company. The enormous pumping capacity is due to a large inlet diameter. It can be easily readjusted to maintain the ideal gap for cutting.

The units feature a case-hardened pump shaft with angular contact ball bearings or cylindrical roller bearings. The impeller is a special casting with hardened cutting edges. It offers higher efficiency with an ideal runner blade geometry. Offering excellent pumping capacity, it is best suited for viscous liquids due to its screw-type impeller center.

www.bauer-at.com

Fisher Pumps

Fisher pumps can be belt driven or direct drive and are available in various motor sizes.

The Fisher manure pump is capable of pumping rocks, pop cans, hooves and many of the other types of debris that find their way into typical manure pits. The particle size going into the pump is regulated by the openings on the rock guard. The impeller design can better accommodate animal hair, straw and hay, which are commonly found in this type of application. For manure screener applications, the high volume of a Fisher manure pump, when equipped with an agitation port, allows for some of the volume to be directed back into the manure pit for agitation.

Fisher pumps use a cantilever shaft that allows the bearings to be placed above the fluid level. This bearing placement minimizes bearing exposure to contamination and helps achieve longer bearing service life. These pumps, manufactured with 1/4” and 3/8” steel plate and heavy walled tubing, utilize a rugged all-welded construction. There is no need to be concerned about assembly bolts working loose or seals and gaskets developing leaks.

In addition to the standard pump sizes offered by the company, custom-made pumps can be manufactured to meet the customer’s needs. Besides the standard electric motor drives, Fisher Pumps offers PTO and hydraulic drive units. Floating pump units for aeration or tail water pumping are also available.

www.fisherpumps.com

Cornell Pump Company

|

Cornell Pump Company, a leader in the pump industry for 60 years, has continued to introduce new pumping equipment for handling manure. Cornell now offers over 25 models of waste handling pump models, with unique and innovative design features for low head transfer to high pressure application in the field. Cornell offers four separate impeller designs to fit the specific pumping

application.

In addition to the existing high-pressure solids handling and grey water handling pump models, recent product additions include high pressure pump models for big gun and injection applications with semi-open impellers that handle stringy materials and slurries. This impeller design also incorporates a cutting action as the product flows through the pump.

Additional pump models have also been added to the product line for lower head transfer applications. Cornell uses its trademarked “Delta” impeller models for applications where straw, twine, and heavier sludges are involved. This impeller design passes almost any material without plugging. Larger models now can pump up to 3,500 gpm.

These models are available close-coupled to electric motors, frame-mounted for flex-coupling to a driver, or SAE mounted direct to an engine bell housing. Also available is the “Redi-Prime,” vacuum-assisted option for automatic priming. Shafts are sealed with a packed stuffing box, the patented “Cycloseal” mechanical seal design, or the Cycloseal with a Run-Dry option.

www.cornellpump.com

Houle & Fils

|

J Houle & Fils Inc is one of the leading manufacturers of manure handling equipment in North America. The company offers a wide range of high quality manure handling products such as the Agi-Pompe with heavy duty undercarriage and also the multipurpose undercarriage. This multipurpose undercarriage allows the use of the Agi-Pompe in lagoons as well as in concrete pits with vertical walls up to 16” deep. The Agi-Pompe features a 6” or 8” directional valve that can be operated while PTO is at low rpm. The gearbox oilbath is protected by a unique greasable three-seal mechanism on each shaft. It can also be equipped with a 20” or 24” propeller with knife kit to shred long bedding. The Agi-Pompe provides constant agitation up to 21,500 US gpm. Operators can choose from a 20” or 26” impeller, and it comes in lengths up to 52’.

www.jhoule.com

Pioneer Pump/Hydro Engineering

|

Hydro Engineering has teamed up with the Pioneer Pump Company to develop a high pressure, high volume manure pump that will handle all dairy, hog and municipal/industrial sludge. The pump can handle volumes up to 1,600 gpm and pressures of 200 psi at 2,200 rpm or lower.

Hydro’s concerns in the development process of this pump were: the plugging of the pump; the cavitation of the pump; to be able to run the pump at lower rpm; to pump high solid content and past a 3” solid; the wear life of the pump; the cost of the pump and replacement parts; the pump must have a run dry mechanical seal; and the horsepower requirement of the pump that requires high performance and efficiency.

The Pioneer 15.5 and 17” impeller pumps have met all of these requirements.

Hydro Engineering 800-833-5812.

Boerger

Boerger has developed a powerfeeder for solids into anaerobic digesters through which solids are mixed into the digestate by a recirculation pump, which has been a big success for the company in Europe.

The Powerfeed SSR – Solids and Substrate feeder offers solids injection into the fluid stream with backflow prevention. The system uses dry material feed, with no added fluid necessary and no fluid phase in the auger hopper. It

features a closed loop digestion system; fluid recirculation flow/digester is not air exposed with solids feed. The system has location and installation flexibility, with various distances to digester possible and it is independent from digester height and type.

Maceration and grinding is done with a twin screw auger. With heavy friction, the SSR achieves homogeneous ground material, minimizing floating material in the digester.

The equipment features a simple control sequence: open valve of recirculation line; start up recirculation pump; start up Powerfeed SSR macerate—pump and solids feed.

The Powerfeed SSR consists of a twin shaft design, with a robust, intermeshing auger pair. The twin screw auger, synchronized and balanced through a heavy duty timing gear, displaces the material smoothly into the backflow preventing SSR twin screw pump, which is housed in a rubber lined casing.

Solids/substrates enter the Powerfeed SSR through the auger hopper. The Powerfeed SSR displaces the material continuously at the open end of the twin screw pump via flanged pipe connection into the fluid flow downstream of the rotary lobe pump. The homogeneous fluid/solids mixture then enters the selected digester.

www.boerger-pumps.com

Balzer

Doda/Balzer’s vertical slurry pumps can handle the toughest slurry jobs, the company says, with their solid performance and features.

The equipment comes in standard lengths of 6’ – 8’ – 10’ – 12’, with other sizes available upon request. Their unique design allows operation of the pump with 2’ offset. Example: an 8’ pump works fine in a 6’ pit with no modifications.

The Doda Super 150 features a stainless steel lower shaft and the pump is galvanized inside and out. The cast, machined impeller is said to have excellent balance and long bearing life. The patented cutter blade system handles trash. From five hp electric to 160 hp PTO drives are available. The impeller pressure plate provides impressive head capabilities and the high-speed impeller with compact housing allows easy pit entries.

www.balzerinc.com

US Farm Systems

|

US Farm Systems, housed in a 45,000 square foot facility in Tulare, California, has over 25 years of experience providing the dairy industry with the finest in dairy waste handling equipment.

Among its products are Electric Agitator Pumps ranging in power from 15 hp to 75 hp, with three-phase motors. These units can mix and pump at the same time and are available in stationary and floating models.

www.usfarmsystems.com

Husky

|

Among the latest in quality manure pumps from Husky Farm Equipment Ltd is the PL490 lagoon pump. This pump is one of the first to have the adjustable wheel carriage and an internal drive line. The PL490 pump has a gearbox in the manure to keep the fan close to the bottom of the lagoon. The gearbox is sealed from the manure with a series of greaseable seals on both sides. The PL490 comes standard in 1,000 rpm and takes a 160 hp engine to operate.

Husky has continued its strong design/engineering trademark with a dual walking undercarriage. This walking undercarriage will go over a straight concrete wall of 14’. Husky will supply an 8” or a 10” discharge pipe on this pump, making the PL490 one of the fastest lagoon pumps at 10,000 gpm.

Husky is a family-owned and operated manufacturing company established in 1962. The company makes quality equipment that operators can depend on, complete with parts books and operators manuals. It has a complete line of equipment from 3”, 4” and 6” electric pumps up to 10” pumps that use up to 200 hp. Husky’s newest propeller is a raceway designed unit with an auger blade and shroud. This will complement the 24’ and 30’ propellers that Husky already

produces.

www.huskyfarm.ca

DM Machinery Inc

|

The newest offering from DM Machinery is the Ultra Flexible Pump.

The company’s lagoon pumps are available with a two- or four-wheel trailer which enables them to enter in aboveground or lagoon pits up to 16’ deep.

The all in-frame drive line is supported by bearings and is equipped with external grease fittings for ease of maintenance; an optional grease bank is

available.

The drive line is partially submerged for better cooling. An interior gear combination allows the hydraulic agitator nozzle on the lagoon models to self-clean as they rotate. Two hydraulic selector valves allow multi-function operations, which also provides less heat generated.

All models are compatible with open or closed hydraulic systems. The turbine pump cover has four sharpened cutting surfaces to reduce the size of solids. To maximize the agitation time, a patented downward spiral auger is equipped with a knife, with additional knifes on the turbine.

Also available from DM Machinery are 4” electric transfer pumps with six curved propeller blades. The drive shaft is mounted on brass bushings for years of durability.

The lower mounted agitation nozzle can be manually turned to allow 340 degrees rotation. The transfer pump adapts to 4” ABS pipe.

Equipped with self-cleaning knife-type guillotine valves, the flow can be easily redirected on the go between, the agitation or filling cycle. The auger mixer with knives allows the rapid cutting, chopping and mixing of solid and liquid substances.

www.dmmachinery.ca

J-Star

The commercial-duty series 8000 lagoon pump from Jamesway is designed for fast agitation and loading, ease of operation, and rugged dependability.

Available in 32’, 42’ and 50’ lengths, the series 8000 pump is designed for tractors with more than 200 hp at 1,000 rpm.

This lagoon pump features a pair of dual tires and extendable legs for added stability, an 8” loading pipe for faster filling, and all hydraulic controls for convenient operation from the tractor seat. Agitation capacity is rated at 7,000 gpm and spreader loading capacity is rated at 3,000 gpm.

www.j-star.com

ABS Pumps

The JS 24 – 84 from ABS Pumps is a professional submersible sludge pump said to have excellent handling ability for sludge, slurry or abrasive water.

The pump is equipped for immediate plug-in start and incorporates a dry running protection. It has low weight for easy handling and low maintenance with the ABS service-friendly modular system. The sludge pump is designed around robust hydraulic parts in wear-resistant nodular cast iron for reliable performance and a vortex impeller for minimum clogging risk. The company says it offers cost-effective pumping with a compact design, and high efficiency and low maintenance requirements.

The ABS pump features robust hydraulic parts for tough conditions combined with lightweight motor components for easy handling. It has an effective and efficient modular system of construction for low inventory costs and easy service.

www.abspumps.com

National Oilwell Varco

|

National Oilwell Varco’s 2500-AG centrifugal slurry pump is proven as a premium lagoon pump, according to the company. The three-vane semi-open impeller is capable of producing high pressures and volumes without clogging. The 2500-Ag centrifugals can pass a 4” spherical solid, and string material such as hay is insignificant. The semi-open impeller design reduces the amount of solids behind the impeller, which increases the life of the stuffing box, impeller and mechanical seal. The 2500-AG impellers are wide, allowing exiting fluid to blend smoothly with recirculating fluid. This reduces eddy flow patterns, essentially reducing wear caused by sand and other abrasive fluids.

Complementing the three-vane impeller is the concentric casing design. The casing is an equal distance from the impeller OD throughout the ID of the casing. This creates a smooth flow pattern and allows the pump to be operated at near shut-in without damage.

The frame is a strong cast iron body with sold base plate. The shaft is 2.5” in diameter at the seal area and 3” in diameter between the bearings. This heavy duty shaft design reduces shaft deflection to less than 5/1,000 of an inch, says the company. A shaft sleeve at the seal area protects the shaft and the bearings are protected by labyrinth bearing cap seals. The 2500-Ag centrifugals utilize top quality bearings engineered for high loads.

www.nov.com

Pacer Pumps

| |

Pacer Pumps has pumps for transferring, re-circulating, spraying, cleaning or filtering and metering. Some pumps are big and burly, others are slim enough to fit narrow neck carboys. The company has horizontal centrifugal pumps direct drive with single seals or magnetic seal-less pumps, as well as self-priming centrifugal pumps or immersion cantilevered pumps with single bearings, for hot or cold solutions.

The company produces a large variety of pumps including engine driven pumps, electric motor driven pumps, hydraulic and pneumatic driven pumps, pedestal-mounted pumps, magnetic coupled pumps, vertical pumps, drum pumps and hand operated pumps.

www.pacerpumps.com