Vaughan Co

Vaughan Co, Inc is the first and only company in the world entirely

devoted to the manufacture of the chopper pump, according to the

company.

Vaughan Co

|

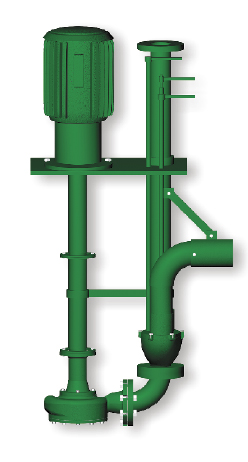

Vaughan Co, Inc is the first and only company in the world entirely devoted to the manufacture of the chopper pump, according to the company. This chopper pump was originally invented by Jim Vaughan over 45 years ago for dairy manure handling in the Chehalis Valley of Washington State.

With 32 patents and over 20,000 units successfully installed worldwide, Vaughan chopper pumps are now utilized by all industries worldwide to handle the most difficult solids pumping applications. In the dairy industry, Vaughan chopper pumps are primarily used for manure pits and lagoons, and are also available with recirculation nozzles for mixing.

Vaughan chopper pumps are designed for severe-duty application, with all cast and heat treated wear components including the impeller, cutter bar, upper cutter and cutter nut. The shaft system includes oil bath lubricated ball bearings with a heavy-duty cartridge mechanical seal designed and built by Vaughan. Pump volute and bearing frame are also cast in ductile iron for long life expectancy.

Vaughan chopper pumps are available in the following configurations: vertical wet well, cantilever, vertical dry pit, horizontal end suction, electric submersible, hydraulic submersible, vertical recirculator, submersible recirculator and self-primer.

Sizes range from 3” to 12” discharge, with flows of 50 to 8,000 gpm and heads up to 280’. Materials of construction are stocked in either ductile iron and steel, 316 stainless steel and CD4MCu heat treated stainless steel.

Vaughan maintains a multi-million dollar parts inventory of all production and wear parts for expedited delivery of both pumps and parts, including many custom orders. All Vaughan chopper pumps are guaranteed in writing for performance and continuous operation without clogging.

www.chopperpumps.com

Accent

|

Accent manure pumps are said to be the only all stainless steel pumps available on the market. The features of the Accent pumps address the major problems farm operations face with pumping manure.

Since the pumps are made from 304 and heat-treated 440C stainless steel, the corrosion factor is eliminated, and material life expectancy can exceed 20 years.

Accent’s wear-heat-treated 440C stainless steel impellers and heavy duty 304 stainless steel cast components provide improved wear resistance, strength and durability. The cast volute cases and machined impeller components feature improved flow characteristics, which result in higher efficiencies—less horsepower is required and the farm experiences lower operating costs.

With the interchangeability of component parts, pumps can be upgraded rather than replaced, meaning fewer spare parts are required.

www.accentmanufacturing.com

ITT Flygt

|

ITT Flygt has a new line of pumps that the company is introducing to the dairy market. The series comes standard with a high chrome impeller specifically designed to pump highly abrasive manure containing sand. Coupled with a VFD (variable frequency drive) the GPM can be as low as 20 GPM and up to 1500 GPM, depending on the size selected. The product line has been designed to pump sand laden manure to solid separators.

www.flygt ron.skinner@itt.com

Vogelsang

Vogelsang pumps are built specifically to take on the harsh conditions of agricultural applications. The company’s rotary lobe pumps have extremely high solids handling ability, giving them the power to pump liquids containing the abrasive solids that are unavoidable when dealing with liquid manure. Vogelsang pumps can operate in forward or reverse on the fly. They can also pull 25ft of suction lift and run dry.

|

The pumps feature a quick-access cover to the wet end which allows easy service in place without removing the pump from the vehicle, hitch or inline assembly. There is no need to remove connected piping, which helps to minimize downtime due to repairs or scheduled maintenance.

When pumping liquid manure, a macerator is required that can not only handle the liquid but is portable and compact. The company’s RotaCut is said to provide good protection for pumps and other downstream equipment from damaging solids suspended within incoming liquids. What sets the RotaCut apart from other macerators is the large heavy duty solids collection basin, the company says. Farm operations working with liquid manure are going to encounter solids and need a unit that can macerate floating solids such as ear tags, hoof trimmings and wooden debris. In addition, the unit must be able to isolate and remove heavy objects such as stones and metal fragments.

www.vogelsangusa.com

Hydro Engineering

|

Hydro Engineering has unveiled two new hydraulic pit pumps, the HP 60 and HP 61. The pumps force feed high pressure pumps for drag hose systems, traveling guns or fill a manure tank wagon. They pump from 800 to 1500 GPM.

Hydro Engineering 800-833-5812.

Fisher Pumps

An age old accepted method of raising the oxygen level of a fluid has been to spray the fluid into the air and let the droplets attract oxygen as they fall to the surface. The Fisher Pump Aerator system has several features that offer improved efficiency and capability.

|

A patent pending air manifold surrounds the intake of the pump. The pre-entrance vortex of fluid, as it passes through the lower air manifold, draws air through the manifold. The air is sheared together with the fluid as it passes through the impeller of the pump. The bubbles of air are much smaller due to this shearing action of the impeller and this greatly improves the surface absorption of oxygen by the fluid.

When the air and fluid mixture discharges from the pump, it passes through a tube equipped with a venture system to allow the air/fluid mixture to bring in added air in high volume for even more oxygen transfer.

The entire mixture is discharged below fluid level to keep the air and fluid together for as long as possible for maximum oxygen transfer. A deflector on the end of the discharge can control the direction of the discharge flow. If the top of the fluid is the area that requires oxygenation, the discharge can be set horizontally. If solids on the bottom are required to be brought into suspension, the discharge can be lowered to a 20 degree angle to agitate the lower areas with the air/fluid mixture.

The directional flow of the air/fluid discharge circulates the fluid enclosure to insure that all the fluid is treated.

The use of two or more units will greatly reduce “dead” areas and insure that all of the fluid is oxygenated. Sprinkler style aerators are inclined to treat the same fluid repeatedly and leave much of the containment area untreated.

An additional advantage of the Fisher Pump Aerator is the ability to shut off the air to the intake manifold and disconnect the venturi discharge. The Fisher Pump can then be used as standard, high volume fluid pump for dewatering or fluid transfer applications.

www.fisherpumps.com

Bauer

|

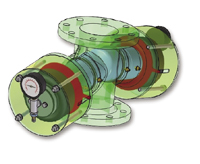

The company’s new automatic pressure regulating Magnum PRV valve (patent pending) is designed for pumps which are operating with both water and liquids with high consistencies. With its unique design, the valve allows the pump to remain in an operating state without cavitation.

Also new from Bauer in its High Performance Pump Series is the SX 2600 slurry pedestal pump and in its High Performance PTO Pumps, the SX 1000 PTO Drive and SX 2000 Engine Mount.

Also from the company, the FAN Separator Submersible Mixer MSX is a submersible motor mixer with a lifting and lowering device and features high efficiency stirring performance. It is designed for all kinds of pits. The unit is said to be suitable for open and closed tanks and is easy to install, operate and maintain.

It features a stainless steel two-wing thrust propeller, a planetary reduction gear unit running in oil bath and a heavy-duty propeller shaft with shoulder roller bearings. The planetary drive has hardened and polished interlocking gears. A streamlined, elegant design is achieved by aligning the motor and propeller on the same axle level.

The submersible three-phase motor has motor thermal guard at the winding, seal rings running in oil bath and special sturdy 8 m cable with strain relief device. The adjustable incline guiding brackets lead to a better mixing efficiency and a faster mixing of floating crusts and bottom sediments, the company says.

www.bauer-at.com

Houle & Fils

J Houle & Fils Inc is one of the leading manufacturers of manure handling equipment in North America.

The company offers a wide range of high quality manure handling products such as the Agi-Pompe with heavy duty undercarriage and also the multipurpose undercarriage. This multipurpose undercarriage allows the use of the Agi-Pompe in lagoons as well as in concrete pits with vertical walls up to 16” deep. The Agi-Pompe features a 6” or 8” directional valve that can be operated while PTO is at low rpm. The gearbox oilbath is protected by a unique greasable three-seal mechanism on each shaft. It can also be equipped with a 20” or 24” propeller with knife kit to shred long bedding. The Agi- Pompe provides constant agitation up to 21,500 US gpm. Operators can choose from a 20” or 26” impeller, and it comes in lengths up to 52’.

www.jhoule.com

Cornell Pump Company

|

Cornell Pump Company, a leader in the pump industry for 60 years, has continued to introduce new pumping equipment for handling manure. Cornell now offers over 25 models of manure handling pump models with unique and innovative design features for low head transfer to high pressure application in the field. Cornell offers four separate impeller designs to fit the specific pumping application.

In addition to the existing high-pressure solids-handling and grey water handling pump models, recent product additions include high pressure pump models for big gun and injection applications with semi-open impellers that handle stringy materials and slurries. This impeller design also incorporates a cutting action as the product flows through the pump.

The latest model added to the product line, 4614M (6” x 4” x 14”), has targeted a competitive product, and produces up to 2000 GPM and up to nearly 200 PSI (1400 GPM @ 168 PSI @ BEP) with a semi-open impeller. Cornell’s newest offering is a higher efficiency, lower maintenance product, with a heavy duty bearing frame, that incorporates a cutting action due to the semi-open impeller operating with an offset intake flange.

These models are available close-coupled to electric motors, frame-mounted for flex-coupling to a driver, or SAE mounted direct to an engine bell housing. Also available is the “Redi-Prime” vacuum assisted option for automatic priming. Shafts are sealed with a packed stuffing box, the patented Cycloseal mechanical seal design, or the Cycloseal with a Run-Dry option.

Cornell continues to expand its high efficiency, heavy-duty, low-maintenance pump product line to meet the ever-changing manure-handling market.

www.cornellpump.com

Pioneer Pump, Inc

|

Pioneer Pump’s complete line of end suction centrifugal pumps are heavy duty and designed to stand up to the toughest applications. Pioneer offers a wide range of both solids handling and clear liquid pump models capable of flows from 50 to 18,000 gallons per minute with solids handling capability up to 4.5” to meet a large range of pumping requirements.

Pioneer offers Ductile Iron construction as standard in most models, with options for special metals including stainless steel and hardened alloys. These units are excellent when it comes to handling manure slurry, manure injection, high pressure clear liquid and fluid transfer applications. Pioneer offers a variety of mounting configurations including diesel driven – skid or trailer mounted, electric driven – close coupled or direct driven, SAE mounted and frame mounted bare shaft options.

www.pioneerpump.com.

Balzer

|

Balzer’s vertical slurry pumps can handle the toughest slurry jobs, says the company, and are said to be ideal for hog, dairy or beef reception pits. Balzer pumps can agitate, transfer or top fill hauling units. Standard lengths are 6’, 8’, 10’ and 12’ (other sizes available upon request). Their unique design allows operation of the pump with 2 ft. offset. The V-6 pump, V-6 with prop agitator, trailer pump and V-8 pump are available. The V-6 pumps 2,500 gallons per minute and theV-8 pumps 4,000 gallons per minute.

The impeller and lower pump housing are constructed of ½” thick abrasive resistant steel. It is designed to cut through heavy bedding and solids.

www.balzerinc.com

Pich International

|

The Pich International Group has exclusive distribution of the Blue Line manure handling equipment. Included in this line-up is the PTS series submersible chopper pump, which features large through-passage, open multi-channel impellers and double chopping system in the suction. These pumps are recommended for particularly heavy applications requiring a preliminary chopping of the solid material contained in the liquid being pumped.

Features include: cutting disc and chopping blades in heat treated stainless steel; double mechanical seal; pump shaft and screws in stainless steel; impeller in treated globular cast iron; innovative double chopping system in front of the suction impeller; casing and housing in fine grain cast iron; 3 phase / 240 volt / 480 volt and 600 volt on special orders.

The pumps are available with 7.5 HP, 10 HP, 12.5 HP, 15HP and 25 HP motors. Smaller horsepowers are available on special requests.

The company has over 12 active dealers and two warehouse locations in the USA.

Brad A. Pich, 250-767-3088 or e-mail Pich04@shaw.ca

Jamesway Farm Equipment

|

The commercial-duty series 8000 lagoon pump from Jamesway is designed for fast agitation and loading, ease of operation, and rugged dependability.

Available in 32’, 42’ and 50’ lengths, the series 8000 pump is designed for tractors with more than 200 hp at 1,000 rpm.

This lagoon pump features a pair of dual tires and extendable legs for added stability, an 8” loading pipe for faster filling, and all hydraulic controls for convenient operation from the tractor seat. Agitation capacity is rated at 7,000 gpm and spreader loading capacity is rated at 3,000 gpm.

www.jameswayfarmeq.com

Boerger

|

Boerger is a key supplier of rotating equipment to the agricultural and biogas industry. The company’s products range from self priming rotary lobe pumps (manure transfer/biosolids injection) to macerating technology to solids feed technology (Powerfeed SSR) for anaerobic digestion processes.

The company’s original product is the PTO driven rotary lobe pump mounted on a 3 Point Hitch. One of the main features of the Boerger rotary lobe pump is its self priming capability. The pump can handle high suction lifts as well as high solids contents making it an ideal workhorse for various manure applications. The unit is equipped with two SAE profile driving shafts, giving the farmer reversible operation. The pump unit is mounted on a corrosion resistant, galvanized base. The galvanized flanges are available in different sizes and can be a fixed or a rotatable set-up, providing a high degree of flexibility.

Boerger rotary lobe pumps are also among the first choices for manure land application equipment. In the US, Boerger pumps are operating on TerraGator NMS. In comparison to centrifugal pumps or vacuum/blower packages, the lobe pump is a positive displacement pump (flow is proportional to operating speed). Therefore the lobe pump is utilized to determine the amount of biosolids land applied.

www.boerger-pumps.com

Husky

|

Husky Farm Equipment Ltd. of Alma, Ontario, has been producing liquid manure pumps and spreaders since 1962.

The H line of manure pumps was invented to handle the large and medium size farm operation with lots of manure. The H5000 pump is an 8” discharge with an optional 10” discharge. The H5000 has an engineered fan to get maximum lift for the horsepower used. The gearboxes are for 85 HP and 120 HP, giving the pump 5000 to 6000 GPM capacity. The H6000 uses a 1:1 gearbox and 160 HP, giving the pump 7000 GPM capacity—if a 10” discharge is used, it’s possible to get 8000 GPM.

The most capacity is achieved from the Husky H10000. With the full 10” discharge, the pump can achieve 10,000 GPM with the same 160 HP.

Any of these Husky H Pumps is available in the 2 point hitch design, adding great stability to the pump and making installation easier.

Each pump comes with a parts book and operator manual.

www.huskyfarm.ca

DM Machinery Inc

|

The newest offering from DM Machinery is the Ultra Flexible Pump.

The company’s lagoon pumps are available with a two- or four-wheel trailer which enables them to enter in aboveground or lagoon pits up to 16’ deep. The all in-frame drive line is supported by bearings and is equipped with external grease fittings for ease of maintenance; an optional grease bank is available.

The drive line is partially submerged for better cooling. An interior gear combination allows the hydraulic agitator nozzle on the lagoon models to self-clean as they rotate. Two hydraulic selector valves allow multi-function operations, which also means less heat is generated.

All models are compatible with open or closed hydraulic systems. The turbine pump cover has four sharpened cutting surfaces to reduce the size of solids. To maximize the agitation time, a patented downward spiral auger is equipped with a knife, with additional knifes on the turbine.

Also available from DM Machinery are 4” electric transfer pumps with six curved propeller blades. The drive shaft is mounted on brass bushings for years of durability.

The lower mounted agitation nozzle can be manually turned to allow 340 degrees rotation. The transfer pump adapts to 4” ABS pipe.

Equipped with self-cleaning knife-type guillotine valves, the flow can be easily redirected on the go between the agitation or filling cycle. The auger mixer with knives allows the rapid cutting, chopping and mixing of solid and liquid substances.

www.dmmachinery.ca

Gorman-Rupp

|

The Gorman-Rupp Company manufactures the 10 and MA Series line of self-priming centrifugal solids handling pumps, with flows of 670 gpm max and 85 ft head max. With the addition of the company’s unique cutter blades and special wear plate, the pumps can be adapted to handle waste, including straw.

The MB series, with standard cutter blade, pumps max 1100 gpm and max 345 ft head, passes 1 ¼” spherical solids.

The M series is designed to handle all types of animal waste and will pass 3” spherical solids. The series features max flows to 1300 gpm and max 106 ft. head, engine or electric driven.

Any pump can clog. Should this happen to an M series pump, farm operations can merely remove the coverplate, clean out the pump interior, replace the coverplate, reprime and begin pumping. Downtime is reduced since suction and discharge plumbing as well as the power source is not disturbed.

www.GRpumps.com