Cornell has incorporated many

unique and innovative design features into its liquid waste slurry

pumps, while maintaining the company’s position in the industry as a

leader of heavy-duty, low-maintenance pumps.

Cornell Pump Company

|

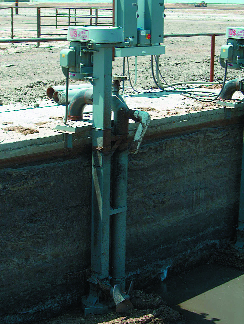

Cornell has incorporated many unique and innovative design features into its liquid waste slurry pumps, while maintaining the company’s position in the industry as a leader of heavy-duty, low-maintenance pumps.

Cornell’s liquid waste slurry pumps have been used successfully in a variety of farm, industrial and municipal waste applications. Their slurry and non-clog pumps are used in big gun applications, injection systems and liquid manure transfer. These pumps are designed specifically to handle manure slurry applications and provide a long service life.

The company’s manure slurry pumps are designed to deal with grey water with 0 to 15 percent solids, and feature both open and closed impellers, handling a range from low to high operating pressures, and low to high flow requirements.

The company’s Redi-Prime system—featuring vacuum assist (diaphram) pumps and the patented Cycloseal and run-dry features—is available on most pumps. It is fully automatic, compact, self-priming and features high hydraulic efficiencies

Cornell’s Delta style impeller is said to be excellent for handling straw, twine, and extremely heavy sludge where there is a low to medium head requirement. The bladed semi-open impeller has a cutting action, which allows it to handle stringy material and the worst slurries at higher heads.

The two- and three-port enclosed impellers are designed to handle solids up to 3.38” and have excellent efficiencies—up to 82 percent.

The grey water impeller has been successfully used in big gun systems, pivot and linear applications with limited solids, high heads and offers efficient operation—up to 88 percent.

www.cornellpump.com

ITT Flygt

|

The F-3000 series of submersible chopper pumps from ITT Flygt Corporation are the toughest and most reliable pumps for handling animal waste, dairy and farm wash-down, poultry wastewater sumps and fibrous waste applications, the company says. Pumps are available in 4” and 6” models, with motors ranging from two hp through 20 hp.

The unique back-swept impeller chops solids 175 times per second—turning material into small easy to pump pieces.

www.flygt.com

Husky

|

The latest in quality manure pumps from Husky Farm Equipment Ltd is the PL490 lagoon pump. This pump is one of the first to have the adjustable wheel carriage and an internal drive line. The PL490 pump has a gearbox in the manure to keep the fan close to the bottom of the lagoon. The gearbox is sealed from the manure with a series of greaseable seals on both sides.

The PL490 comes standard in 1,000 rpm and takes a 160 hp engine to operate. Husky is producing it in a standard length of 42’, with other lengths to follow shortly.

Husky has continued its strong design/engineering trademark with a dual walking undercarriage. This walking undercarriage will go over a straight concrete wall of 14’. Husky will supply an 8” or a 10” discharge pipe on this pump, making the PL490 one of the fastest lagoon pumps at 10,000 gpm.

Husky is a family-owned and operated manufacturing company established in 1962. The company makes quality equipment that operators can depend on, complete with parts books and operators manuals. It has a complete line of equipment from 3”, 4” and 6” electric pumps up to 10” pumps that use up to 200 hp. Husky’s newest propeller is a raceway designed unit with an auger blade and shroud. This will complement the 24’ and 30’ propellers that Husky already produces.

www.huskyfarm.ca

Bauer

|

The powerful chopper of Bauer’s Magnum pumps can handle up to 12 percent solids. The pumps feature a radial housing and their large-dimensioned pumping channel ensures unobstructed delivery of viscous liquids. The rinsing connection is designed for flushing the seal chamber with clean water to keep fibers and solids from settling. The result is higher operational safety and longer pump life. The pumps have compact spur gearing with case-hardened helical gearing running in an oil-bath. With the cutting flange, the high-grade casting and hardened cutting edges guarantee long life. It provides excellent cutting performance on cutting edges and impeller, says the company.

The enormous pumping capacity is due to a large inlet diameter. It can be easily readjusted to maintain the ideal gap for cutting.

The units feature a case-hardened pump shaft with angular contact ball bearings or cylindrical roller bearings. The impeller is a special casting with hardened cutting edges. It offers higher efficiency with an ideal runner blade geometry. Offering excellent pumping capacity, it is best suited for viscous liquids due to its screw-type impeller center.

www.bauer-at.com

US Farm Systems

|

US Farm Systems, housed in a 45,000 square foot facility in Tulare, California, has over 25 years of experience providing the dairy industry with the finest in dairy waste handling equipment.

Among its products are Electric Agitator Pumps ranging in power from 15 hp to 75 hp, with three-phase motors.

These units can mix and pump at the same time and are available in stationary and floating models.

www.usfarmsystems.com

Fisher Pumps

|

Fisher pumps can be belt driven or direct drive and are available in various motor sizes.

The Fisher manure pump is capable of pumping rocks, pop cans, hooves and many of the other types of debris that find their way into typical manure pits. The particle size going into the pump is regulated by the openings on the rock guard. The impeller design can better accommodate animal hair, straw and hay, which are commonly found in this type of application. For manure screener applications, the high volume of a Fisher manure pump, when equipped with an agitation port, allows for some of the volume to be directed back into the manure pit for agitation.

Fisher pumps use a cantilever shaft that allows the bearings to be placed above the fluid level. This bearing placement minimizes bearing exposure to contamination and helps achieve longer bearing service life.

These pumps, manufactured with 1/4” and 3/8” steel plate and heavy walled tubing, utilize a rugged all-welded construction. There is no need to be concerned about assembly bolts working loose or seals and gaskets developing leaks.

In addition to the standard pump sizes offered by the company, custom-made pumps can be manufactured to meet the customer’s needs. Besides the standard electric motor drives, Fisher Pumps offers PTO and hydraulic drive units. Floating pump units for aeration or tail water pumping are also available.

www.fisherpumps.com

Houle

|

J Houle & Fils Inc is one of the leading manufacturers of manure management equipment in North America.

To rapidly homogenize and pump liquid manure in a pit up to 16’ deep, the company has a new 1,000 rpm speed reducer with timing belt that is now available on three-point, hitch articulated Agi-Pompe and Super Pompe. This 1,000 rpm option includes a 77 Series joint protected by an oil bath.

www.jhoules.com

ABS Pumps

The JS 24 – 84 from ABS Pumps is a professional submersible sludge pump said to have excellent handling ability for sludge, slurry or abrasive water.

The pump is equipped for immediate plug-in start and incorporates dry running protection. It has low weight for easy handling and low maintenance with the ABS service-friendly modular system. The sludge pump is designed around robust hydraulic parts in wear-resistant nodular cast iron for reliable performance and a vortex impeller for minimum clogging risk. The company says it offers cost-effective pumping with a compact design, and high efficiency and low maintenance requirements.

The ABS pump features robust hydraulic parts for tough conditions combined with lightweight motor components for easy handling. It has an effective and efficient modular system of construction for low inventory costs and easy service.

www.abspumps.com

N-Tech

|

N-Tech, a division of NTH, Inc of Barron, Wisconsin, has introduced a new trailer model irrigator feed pump modeled after the solid design of all N-Tech trailer pumps.

The new hydraulically powered pump will feed irrigation pumps in the 1,000 gpm range.

It will run off high volume tractor hydraulic systems or separate power packs. The standard length of 34’ reaches well into most storage basins or lagoons, according to the manufacturer.

www.ntechpumps.com

Gorman-Rupp

|

Gorman-Rupp Company manufactures the 10 & MA series line of self-priming centrifugal solids handling pumps, with flows of 670 gpm max and 85 ft head max. With the addition of their unique cutter blades and special wear plate, the pumps can be adapted to handle waste, which includes straw.

The MB series, standard with cutter blade, pumps max 1,100 gpm and max 345 ft head, passing 1-1/4" spherical solids.

The M series, designed to handle all types of animal waste, will pass 3" spherical solids. It has max flows to 1,300 gpm and max 106 ft. head, engine or electric driven. Any pump can clog. But should this happen to an M series pump, the coverplate can be removed, the pump interior cleaned out, the coverplate replaced, then simply reprime and begin pumping.

Downtime is reduced since suction and discharge plumbing as well as the power source is not disturbed.

www.gormanrupp.com

Balzer

|

Doda/Balzer’s vertical slurry pumps can be counted on to handle the toughest slurry jobs.

The pumps come in standard lengths of 6’, 8’, 10’ and 12’, with other sizes available on request. Their unique design allows operation of the pump with 2’. offset. Example: an 8’ pump works fine in a 6’ pit with no modifications. This is a pump said to be ideal for hog, dairy or beef reception pits.

Doda’s easy turn nozzle system allows operators to rotate nozzles 320 degrees

horizontally, even under full power. Vertical nozzle adjustment is 90 degrees. The high-pressure hose on the mixing nozzle prevents waste spraying all over and aids in sustaining the pump’s tremendous pressure.

Livestock operations can also choose from Balzer’s horizontal slurry pumps. Slurries with high concentrations of solids, straw, or bedding, weeds etc, are no

problem for these pumps. The patented chopping system handles the toughest jobs, guaranteed, says the company. Easy priming, high pressures and tremendous suction sets Balzer horizontal slurry pumps apart. PTO, diesel, or gas engine and electric motor models are available.

Direct drive pumps have an oil bath bearing system and mounting pedestal. They can be used with diesel and gas engines or electric motors. High tech tungsten carbide seal on the pumps give long life. Heavy duty gear boxes have a variety of gear ratios.

The patented chopping system utilizes a cutter blade-counter blade design. Blades are hardened steel alloyed with manganese and vanadium.

www.balzerinc.com

J-Star

|

The commercial-duty series 8000 lagoon pump from Jamesway is designed for fast agitation and loading, ease of operation, and rugged dependability. Available in 32’, 42’ and 50’ lengths, the series 8000 pump is designed for tractors with more than 200 hp at 1,000 rpm.

This lagoon pump features a pair of dual tires and extendable legs for added

stability, an 8” loading pipe for faster filling, and all hydraulic controls for convenient operation from the tractor seat. Agitation capacity is rated at 7,000 gpm and spreader loading capacity is rated at 3,000 gpm.

www.j-star.com