Features

Anaerobic Digestion

Manure Application

Manure Manager’s top stories of 2019

From digesters to higher corn yields, Manure Manager recounts the top read stories of this year.

December 18, 2019 by Manure Manager

A Martin Energy Group mini digester located on the farm of Rob McKinlay in Beachville, ON. Photo courtesy of Martin Energy Group/Harcolm Farms.

A Martin Energy Group mini digester located on the farm of Rob McKinlay in Beachville, ON. Photo courtesy of Martin Energy Group/Harcolm Farms. 1. Mini digesters: Small profile, big future

After seeing success in Europe, mini digesters are entering the North American market with great potential. A mini digester is not so much a project but a product, costing a fraction of a full-sized digester. Mini digesters are sized at 10 to 50 kilowatts and are designed to be able to run on farm waste alone.

2. Considering windrow composting

Nutrient runoff is always a hot topic, but especially recently as concern for the environment grows. A Wisconsin study looked at improving water quality through windrow composting.

3. Transforming litter to clean energy

Güres Group, based in Turkey, uses Turboden’s Organic Rankine Cycle (ORC) turbine to transform 500-tons of poultry litter a day into clean energy. The ORC system is used in place of water and transforms the input heat into electrical power.

4. How much is that manure worth?

The University of Minnesota developed an online manure value calculator in 2019 that helps determine values, based on the type of manure you have available and its nutrient content.

5. Not all poultry litter is the same

Moisture and nutrient content varies whether it’s coming from hens, boilers, pullets, or turkeys. This profile of Pierce Litter, a custom nutrient management contractor, shows how honesty about nutrient content is the foundation for a good business.

Reinford Farms hired Martin Construction to assist in applying for grant funding and to design the digester. Construction began in 2007 and was finished in 2008.

6. Finding success with an on-farm digester

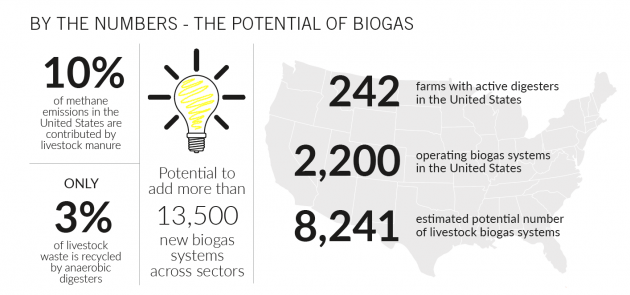

It’s no surprise that a digester story made the list. Interest for anaerobic digestion has been surging as more operations look for ways to reduce odor and better manage manure.

7. Seeding cover crops and injecting hog manure in one pass

A machine, designed by Pennsylvanian hog farmers, can simultaneously side-dress corn with liquid hog manure, while planting a cover crop. Read about how the idea came to be and the results so far for corn yields and the environment.

The Gutshalls first demonstrated their new machine design at the North American Manure Review in Chambersburg, Pa., in 2015.

8. Using manure to produce liquid nitrogen fertilizer

A new system that has the potential to revolutionize the benefits of manure is currently on trial in two European countries. The new concept, developed by Norwegian company N2 Applied, involves passing manure or digestate through a plasma reactor to produce liquid nitrogen fertilizer.

9. Researchers find multiple effects on soil from manure from cows administered antibiotics

A 2019 study led by Colorado State University and the University of Idaho found multiple effects on soils from exposure to manure from cows administered antibiotics. Some of these effects include alteration of the soil microbiome and ecosystem functions, soil respiration and elemental cycling.

10. Composting or stockpiling – What’s the difference?

What is stockpiling? What is composting? Most importantly – what are the differences and what does this mean for the breakdown of manure.

Honorable Mentions

11. Stories about anaerobic digestion

While articles on manure handling always dominate, stories about anaerobic digestion were next in line when Manure Manager staff took a look at what articles were trending in 2019. Whether it was news about new digester projects, investment announcements, or interesting collaborations, the interest was there.