Uncategorized

Sponsored Content

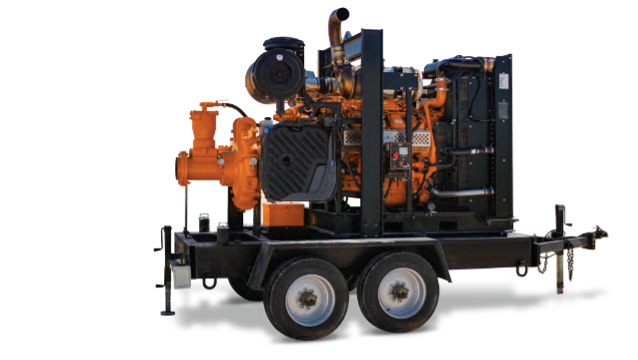

Engineered to pump up your bottom line

June 7, 2021

Sponsored by PJE

With more than 125 years’ experience developing engines, Scania is recognized for cutting-edge technology and unrivaled reliability in numerous industrial applications around the world. Pumps powered by Scania engines are hard at work 24/7/365, providing solutions for a diverse and demanding list of industries, including Oil & Gas, Construction, Mining, Agriculture, Municipalities, Dewatering and others. Scania’s reputation for unsurpassed dependably has also made our engines a prime choice for the pump rental industry. Keep your profits flowing. Trust Scania to power your pumps.

POWERFUL PERFORMANCE

Scania’s streamlined engines are high-performing machines with a strong power-to-weight ratio. When powered by Scania, pump operators can expect instant response, uncompromising torque at low RPMs, and agile performance at any speed. Scania power is available for utilization whenever needed and makes hard work efficient, even during long, grueling projects.

Scania offers a powerful lineup of 9L, 13L, & 16L Tier 4 Final engines ranging from 275hp – 770hp.

NO DPF. NO REGENERATION. NO WORRIES.

The innovative Scania Tier 4 Final solution is the result of years of research and technological development by our engineers. Scania’s system uses a combination of Selective Catalytic Reduction (SCR) and Exhaust Gas Recirculation (EGR) to achieve Tier 4F emission level requirements. This is accomplished without the need for a Diesel Particulate Filter (DPF), so Scania’s solution does not have any regeneration cycles. This affords Scania engine users the opportunity to worry about more important aspects of their operations than downtime resulting from regeneration.

COMMON PARTS = STRONG INVENTORY

Scania engines utilize common parts across all three engine models and their central US warehouse consistently maintains a 98% fill rate for parts orders. All three engines have inter-changeable cylinder heads resulting in a simplified parts inventory. By having common parts, technical training times are reduced. The Modular Concept also supports the Through implementing a modular “One Man Service Concept,” most major repairs can be performed on-site resulting in more uptime for your equipment including cylinder head repairs.

Scania Service Network

SMART SUPPORT, powered by Scania was developed in order to safeguard the quality of service received and to maximize uptime for every customer. The major components of Smart Support are Training, Scania Assistance, Strategically Located Service Points, Modular Concept, Parts Availability, Scania Handshake and Tailored Support. Scania’s service network includes over 700 technicians trained on the latest emissions standards and technology. Scania Assistance (1-800-2-SCANIA) provides customers with a 24-hour reporting line for any service issues they may face.

The combination of highly reliable products, innovative Tier 4 Final solution with no Diesel Particulate Filter (DPF), strong after sales parts availability and Smart Support ensures your operation stays up and running.