Features

Anaerobic Digestion

Energy

Energy Production

Environment

Sustainability

Detecting leaks in biogas plants by laser

March 16, 2015 by Manure Manager

Researchers have developed a demonstrator that, without making contact, detects biogas or natural gas escaping from leaks through the use of a laser. Contributed

Researchers have developed a demonstrator that, without making contact, detects biogas or natural gas escaping from leaks through the use of a laser. Contributed

Servicing biogas plants is challenging. Methane leaks are particularly problematic – from a security, a technical, an economic as well as an environmentally friendly perspective. Researchers are working on a technique that helps to better detect leaks. In this process, a laser discovers the leaks from several meters away.

The requirements for the operation and maintenance of gas plants are high. Leakage is particularly problematic. Even small leaks from the joints of the gas lines or fermenters can have consequences. Escaping methane can result in fires, economic damage and a worsening of the carbon footprint of the gene-rated electricity.

In a project funded by the German Federal Ministry of Food and Agriculture (BMEL), researchers and a measuring equipment manufacturer are now addressing this issue. After 18 months, the experts have developed a demonstrator that, without making contact, detects biogas or natural gas escaping from leaks through the use of a laser.

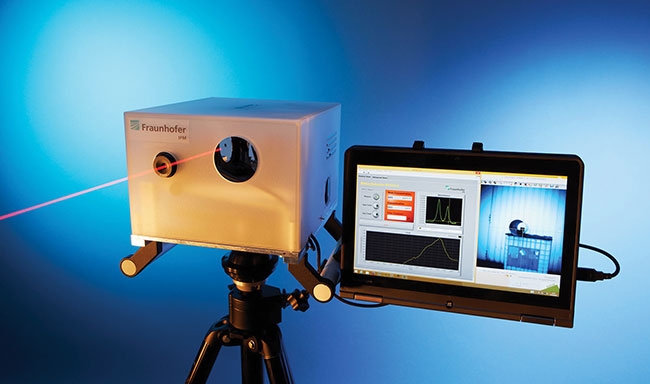

The technology developed at the Fraunhofer Institute for Physical Measurement Techniques IPM in Freiburg, Germany, is based on optical emission and backscattering spectroscopy. In the process, the light of a strong laser beam detects escaping methane. Simultaneously, the gas irradiates part of the light back. The scientists analyze this proportion and determine the gas concentration from the absorption spectrum of the escaping substance. Since the gas spectrum is very precise, only methane is very selectively measured, and not any other gases. The technology is located in a box-shaped demonstrator. It stands on a three-legged tripod and is directed at the part of the equipment that is to be inspected. The optical portion of the measurement system comprises the laser, detector, camera and range finder. A connected tablet PC collects the data and evaluates it. The screen displays the graphically edited information concerning the escaping methane and the exact position of the leak. Measurements from up to 15 meters of distance are possible.

Dr. Johannes Herbst, measurement technology expert at the Fraunhofer IPM, expects the technology to be ready for the market in the next three to five years.

“In the future, the measurement team will be able to easily check the entire system from the ground. It used to be necessary to climb ladders and identify the leaks on the spot,“ said Herbst.