Meadowlane Farms adds a waste application business to its environmentally responsible portfolio.

Meadowlane Farms in Frankfort, Indiana, is a shining example of a well-run CAFO. Students, politicians and county officials have come to tour the facility and see first-hand what environmentally responsible farming is all about.

|

| The biggest manure application challenge faced by Meadowlane Farms is the weather, since Indiana regulations require that ground be dry for application. |

In fact, the farm has received two recent awards – the National Pork Checkoff Board’s 2007 award as well as the Governor’s Award for Environmental Excellence. When you ask owner Mike Beard why he works so hard to be environmentally friendly, he says it’s simple. “Protecting the environment is the right thing to do, and that’s what we’re about today in agriculture. We need to earn the public’s trust and prove to them that we deserve their trust.”

Lay of the land

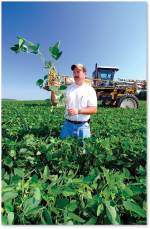

Meadowlane is a family operation. In the 1980s, Mike and his wife, Pamela, used to milk cows alongside Mike’s father, Robert. As the years went by, the farm evolved from cattle to swine. By 2002, the one-time dairy had fully transformed into a 15,000 hog contract finishing operation with 1700 acres of corn and soybean. Pamela is no longer working on the farm, but their son David, son-in-law Chris Pearson, and Mike’s stepbrothers, Mike and Don Burkhalter, have come on board.

Mike says they built three 4000 head contracted finishing barns and

converted three 1000 head barns. Each barn has a slat floor/deep pit

and the 4000 head buildings can store approximately two million gallons

of waste, while the 1000 head buildings hold approximately 500,000

gallons. “That’s enough capacity for once-a-year removal,” he says.

It became apparent early

on that they were going to have to move a lot of waste in a hurry. They

found the technology that suited their situation, but it was not cheap.

So, in addition to a significant personal investment, they also secured

grants from the Indiana Department of Environmental Management and the

Natural Resources Conservation Services (NRCS) equipment program.

|

| Meadowlane is a family operation with a 15,000 hog contract finishing operation and 1700 acres of corn and soybeans. |

|

| The family has built and converted various finishing barns on the property. Each barn has a slat floor/deep pit with enough capacity for once- a-year manure removal. |

|

| Many of Meadowlane Farms’ manure application customers share a boundary with close neighbors – sometimes a subdivision – meaning odors have to be kept to a minimum. |

Efficient and odor free

Today, the application system is quick, efficient and high-tech. Meadowlane starts by agitating the waste in the pits. The waste is then pumped from the pits with a hand-built 855 Cummins pump, through a drag hose and out to the field. “As long as we’re within 1.5 miles, we have enough hose to reach that applicator, which is mounted on a tractor in the field,” says Mike. The nutrients are then injected approximately four inches below the soil surface.

The tractors are the high-tech component. The AGCO DT240A and a New Holland TG 305 are both fully equipped with satellite-based steering, variable speed transmissions, data collection, yield mapping and flow meters. With a one-year crop rotation, Meadowlane fertilizes about half of its 1700 acres annually. They can access approximately 600 to 700 acres with this closed loop system. For the remaining acreage, they use semi tankers.

The farm’s tankers are approximately 8500 gallons each. “Using one of our six pumps, we can fill each tanker in about three to five minutes,” says Mike. “In the field, we draw off the tanker and through a hose to supply the tractor.” Mike says he saves approximately $150 per acre on commercial fertilizer and feels the manure is better for the crops as well. “Our soils aren’t the best soils in Indiana. So, the addition of the phosphorous and potash is welcome. We’re also getting organic matter that we don’t get with a commercial fertilizer. And the nitrogen is, I believe, more effective in the form that the manure supplies it.”

Inadvertently creating a new business

Once the farm got the system up and running, it was faster than they expected. “We pumped the first barn in four days,” recalls Mike. It wasn’t long before neighbors started asking if Mike could do the same for them and Meadowlane’s manure application business was born.

“The first year (2002), we applied two million gallons,” says Mike. “Last year, we helped the neighbors do about 30 million gallons.” Their customers are all within a 20 mile radius. And they transport the equipment on planter trailers. “Our equipment isn’t very long,” says Mike. “I can back up to the planter trailer and put the equipment on, lift it back up, and then roll down the road quite easily. It’s pretty narrow – maybe nine feet.”

Mike’s son, David, and son-in-law, Chris Pearson, handle the application business and will soon add a couple of part-time employees. They find the biggest challenge is the weather since Indiana regulations require that ground be dry for application.

David and Chris also run into soils on customers’ land that do not absorb the manure when injected, which can provide an opportunity for the waste to get down to the drainage tile. “For those cases, we built an injection system using the Gen-Till system,” explains Mike. “It pokes holes in the ground and lifts the soil. Then we spray the manure behind it. The manure then soaks into the ground easily. It doesn’t go deep and stays in the top surface layers of the soil. We also use the Gen-Till system when we’re applying low nutrient waste out of customers’ lagoons,” he adds.

One challenge they have not had to deal with is odor. “Some of our customers share a boundary with close neighbors – sometimes a subdivision,” says Mike. “When we tanker that manure to those farms, the neighbors are impressed that they don’t smell anything. If they do smell anything, that smell is gone in 12 hours and it’s not strong.”

Keeping up

The manure application business is doing so well, they have actually had to turn some customers away. Part of the reason for their booming business is the expense for other farmers to purchase a similar system.

“When we started out, we had grants and we remodeled pieces of equipment,” says Mike. “As we’ve grown, we have purchased better equipment. And it’s usually been higher volume equipment. But to just go out today, bare bones, and buy this stuff. You would to have to have pretty deep pockets.”

The responsible farmer

Mike, a self-proclaimed environmental advocate, sees a bigger picture when it comes to responsible farming than just good manure management practises. On the farm, Mike has:

- created wildlife habitat,

- installed grass buffers around many of the waterways to conserve soil,

- established buffers around State of Indiana woodlands,

- used trees to keep odors down,

- maintained the buildings and sited in areas less visible to the public.

“I’ve had the feeling for many years that my neighbors were getting further and further away from the farm – being exposed to them,” Mike says. “In Indiana, we began to see opposition to CAFOs (Concentrated Animal Feeding Operations) and I became involved with the local farm bureau.”

Mike took ‘involvement’ to the next level. Here are just a few of the projects he has been involved in.

• Farming the Courthouse – This County Farm Bureau and State project brought county officials to Meadowlane to educate them about the value of CAFOs, dispel myths and answer questions. It won national recognition from the American Farm Bureau Federation.

• Pork Advocacy Coalition – This voluntary group lobbies the state and national legislators on behalf of the pork industry. Mike has been on the board since its inception and has also chaired it.

• Farm Visits – When the governor, an advocate of Indiana pork production, ran for office, Mike invited him out. “He came and toured the barn. He got close enough to one of the hogs that he claims it bit him. Whether it did or not, it made one whale of a good sound bite for his run for election.” Mike has also had visitors from China, the NRCS Secretary, and a young agriculture aide from Washington who went on to be a State legislator.

• Pork Ambassador – Mike has been invited to Central America to represent the pork industry. Last fall, Mike accompanied the governor to Japan, trying to encourage the Japanese to invest in Indiana agriculture.

Mike believes environmentally conscious involvement is vital to the industry. “CAFOs are coming under fire in different areas of the state,” he says, “and if we can trot out an award for protecting the environment, it lessens the sting of the rhetoric. We’ve got to convince our neighbors who are scared of this stuff that comes out from under the buildings, that what we’re doing is the right thing to do with it,” he adds. “We’re capable. And we’re responsible.”

Even David and Chris get into the act when they go out to pump at a facility. They talk to the operator or owner about soil maps, help determine how much of the waste needs to be applied, and work to mitigate the loss of the nitrogen through the air and the water.

Future goals

Mike says he would like to build more barns in the future – if he can pair them with a methane generation site. But there are engineering logistics and economic issues yet to work out and, since Meadowlane does not have an odor issue, Mike doesn’t see a lot of return from the odor mitigation that methane would afford.

“I’m not one of these people that wants to see long-term results,” he adds. “I want to see something returned fairly quickly. I’m not satisfied with a four percent return.”

Until then, Mike will have to just continue being a true advocate of exceptional farming practises – a man who walks the walk.

|

|

|

| Mike Beard has created wildlife habitat and installed grass buffers around many of the waterways while also establishing buffers around woodlands. |

On soils that don’t absorb the manure readily when injected, the Beards used the Gen-Till system to build an injector that pokes holes in the ground and lifts the soil so the manure can soak in easily. |

|

|

|

|

David Beard (above) and his brother-in-law Chris Pearson handle Meadowlane Farms manure application business. |

Tractors at Meadowlane Farms are fully equipped with satellite-based steering, variable speed transmissions, data collection, yield mapping and flow meters. |

|

|

|

|

| Chris Pearson examines a soybean plant growing on Meadowlane Farms. |

Indiana pork producer, Mike Beard takes the term ‘involvement’ to a whole new level, opening his farm to government and international visitors, serving as an ambassador to the industry, being one of the National Pork Checkoff Board’s 2007 award winners and receiving a Governor’s Award for Environmental Excellence. |

|

|

|

|

| Waste from Meadowlane’s operation is agitated in the pits before it is pumped – using a hand-built 855 Cummins pump – into tankers or through a drag hose out to the field. |

Each of Meadowlane’s semi tankers can haul approximately 8500 gallons of liquid manure. | |

|

|

|

Meadowlane Farms fertilizes about half of its 1700 acres annually. A closed-loop system, which uses a drag hose injector system fed direct from the barn pits, can access approximately 600 to 700 acres. |

Meadowlane Farms produces about 1700 acres of corn and soybeans in a one-year crop rotation. |