The Liquid Waste Technology, LLC

(LWT) Pit Hog Remote Control Electric Lagoon Pumper (Model PH10-40hp)

dredge is designed to remove sediments from the bottom of waterways,

settling lagoons and ponds. In situ solids are excavated and

transported as slurry through a piping system to a remote location.

Liquid Waste Technology LLC

|

The Liquid Waste Technology, LLC (LWT) Pit Hog Remote Control Electric Lagoon Pumper (Model PH10-40hp) dredge is designed to remove sediments from the bottom of waterways, settling lagoons and ponds. In situ solids are excavated and transported as slurry through a piping system to a remote location. The material excavated is normally land applied, trucked or dewatered.

Foam filled, steel pontoons provide the necessary flotation to support the machinery and equipment in the waterway. Principle features include the auger head, submersible pump, boom, boom hoist, traverse winch and hydraulic system. The auger head and the submersible pump are essential to effective solids removal. The boom hoist vertically positions the auger and submersible pump in the sediment while the traversing winch propels the machine forward and backward along a wire rope cable anchored at both ends. This proven design provides a cost-effective means for hydraulically dredging sediments.

Prior to operation of the dredge, an anchored cable harness is established for positioning and propelling the unit in the waterway. Generally, the harness is comprised of two lateral cables located on opposite sides of the pond with a traverse cable stretched between them. The traverse cable is threaded through the treble sheave winch and cable guides on the unit which, after pre-tensioning the cable to remove the slack, propels the unit forward and backward. After the floating discharge hose and/or pipe are connected to the dredge, it is ready to operate. Generally, solids are excavated while traversing forward only.

All dredge functions can be remotely controlled from shore using a hand-held transmitter, or run via complete automation developed by LWT. A series of switches on the transmitter enable the operator to start and stop all equipment as well as set the speeds of the slurry pump and winch traverse.

LWT’s automated and radio remote controlled dredges use Bottom Sense to protect pond bottoms and liners, Solids Sense to maintain delivery of a constant solids density and other options, such as Radio Remote Sense, Auto Sense and Lateral Sense.

The dredge is designed with quality components for dependable, easy operations and built with structural steel for dependable, long-term use. It utilizes electric power, can be manned or unmanned, and can be operated by computer or manual controls.

www.lwtpithog.com

Reef Industries

|

When a farm project requires a great deal of a lagoon liner and a special material to offer a balance of properties necessary to best meet those needs, producers may want to consider Reef Industries’ Permalon tank liners. Permalon offers outstanding chemical resistance, weathering characteristics and the highest weight to strength ratio available. This alloyed, high density polyethylene laminate resists punctures and tears for a more secure system. Designed to be lightweight and very easily handled, Permalon ensures a cost efficient installation.

Permalon is also available in heavy-duty, internally scrim reinforced construction and with a geotexile composite for difficult site conditions. Custom fabrication is available for specific project requirements. Custom engineered fabrication and sizes up to 200ft x 200ft are available to minimize in-field seaming and include three-dimensional shapes for box and container liners. Individual panels of an acre in size are readily done, always minimizing and often eliminating the need for expensive field installation crews. Permalon is a non-toxic material so it will not affect the health of your crop.

www.reefindustries.com

Industrial & Environmental Concepts

|

IEC, a company with 16 years experience designing, fabricating, and installing industrial cover and liner systems, designs its products to provide many years of lasting service in a variety of environments and applications. Since 1993, the company has designed, fabricated and installed more than 250 projects involving odor control, gas collection, pond liner systems and tank liner systems.

IEC’s Odor Control & Gas Collection Covers are specifically designed for each client utilizing a variety of material options. Cover applications can be used with any type of gas collection from water basin and keep rain and snowmelt water separate from wastewater under the cover. Advantages of a cover include installation without site interruption, use on tanks or lagoons, elimination of rainwater ponding problems, elimination of gas ballooning, provides high buoyancy and rigidity, hatches can provide access to in-basin equipment, improved quality with pre-manufactured panels and are fabricated at IEC’s plant, so field welding is not required.

IEC also has a patented Modular Cover System comprised of a series of individual casings connected together to form a complete floating cover system. Each individual casing consists of a panel of closed cell insulation encapsulated between two sheets of durable geomembrane. The result is a unique floating cover system that provides insulation values ranging from R-2 to R-30; and is engineered and manufactured to specific dimensions/basin requirements.

The Modular Cover System offers the following advantages over conventional covers systems:

• maintenance free,

• can be installed on tanks or lagoons,

• adepts to varying water levels,

• individual casings are removable,

• installed without site interruption,

• shorter installation time, no field welding required,

• installation requires less heavy equipment,

• eliminates rainwater ponding problems,

• eliminates gas ballooning,

• high buoyancy and rigidity,

• hatches can provide access to in-basin equipment.

www.ieccovers.com

Curry Industries

|

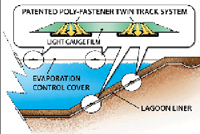

Curry Industries Limited’s products and innovations have delivered benefits to customers and the environment for more than 30 years. The company’s newest product, the Poly-Fastener Twin Track System, is designed for installing evaporation control covers and lagoon liners. It offers small landowners and livestock producers an affordable, efficient and reliable alternative as opposed to the traditional, time consuming and costly methods of joining together poly film, such as heat welding, stitching or tape seaming.

The Poly-Fastener Twin Track System has the ability to fasten two sheets of light gauge poly film (6.0mm to 20mm thick) together. This two-part, plastic extrusion profile is a channel with an insert strip, which easily snaps the poly in place. According to company research, this is the only mechanical device in the agricultural and geomembrane industry that can join plastic film together without overlapping.

Why choose the Poly-Fastener Twin Track System? Quick and suitable for do-it-yourself, on-site application. Installation can occur in almost all weather conditions. Long lasting, UV resistant and can withstand temperatures as low as minus 40 degrees F. Highly compatible with light gauge film, the product is more economical than heavy gauge film.

Curry Industries supplies product and installation tools to meet the customer’s specific needs. The system will assist the buyer in creating an economical and environmental solution for manure waste containment, irrigation/reservoir liners, odor control, evaporation control, gas collection systems and many more applications.

www.curryindustries.com

American Structures Incorporated

|

American Structures Incorporated (ASI) is a trusted manufacturer of bolted stainless steel tanks for animal waste storage. The company has 30 years of experience and, coupled with the superb qualities of stainless steel, allows them to deliver product in a timely manner. The manufacturing and building processes employed by ASI allow for a shorter build time, meaning less downtime and interruption in daily business on the farm.

The company’s bolted storage tanks can be easily expanded without changing the storage system or tank design, offering greater versatility, as well as the ability to grow with operation needs. ASI offers personalized products and services and is dedicated to developing innovations designed to help the environment at the best dollar value for customers.

Farmers interested in adding a methane generator to their farm should know that ASI’s bolted stainless steel tanks use less room and offer the durability and long-lasting use necessary to effectively manage manure storage.

The company continues to expand its abilities and expertise about digesters and methane generators and looks forward to working with customers on specialized design and custom planning.

www.ameristruc.com

Siemens Water Technologies

|

The new E-Ball environmental ball system from Siemens Water Technologies consists of multiple hollow plastic balls that are used to create a floating blanket to cover virtually any water surface, including manure ponds and tanks. The plastic balls, which come in a variety of sizes and construction materials, typically measure 100mm in diameter, weigh 220g and are made of medium density polyethylene. The low thermal conductivity of plastic, combined with air held in the ball, creates a thermal insulation barrier over the water surface.

The E-Ball system components feature a thick wall construction that is approximately 10mm thick, yet floats with about 40 to 50 percent of the ball surface submerged to optimize the insulating effect and minimize the chance of the ball blowing out of the tank. The heavy-weight construction also eliminates the need for plugs, seals, or ballast. Totally maintenance-free, the E-Ball system components will not leak or sink. Ultraviolet stabilizers protect the plastic from degrading in the sunlight.

The environmental balls form a close-packed configuration and stack up or spread out in sloped basins to maintain total surface coverage as the water level changes. The balls also automatically conform to the shape of equipment and basin structures, allow normal movement of equipment through the liquid and do not impede installation of monitoring probes or water sampling.

The E-Ball floating tank and lagoon cover reduces odors substantially. It can be used as a stand-alone product or combined with floating surface aerators and mixers or other aeration and mixing technologies.

www.siemens.com

Engineered Storage Products Company

|

Slurrystore, a division of Engineered Storage Products Company, bills itself as being the number one above ground manure storage system on the market. The company provides three different models of above ground, glass coated steel manure storage tanks – Model 90A, Model 96A and Model 2000. All structure components:

• are glass coated for high corrosion resistance and long life,

• have built-in agitation systems to thoroughly blend nutrients contained in the livestock waste,

• conform to USDA-NRCS regulations,

• are convenient, durable and safe with an optional containment detection system,

• are manufactured in an ISO 9001 Quality System Certified facility.

Based on the model chosen, there are dozens of options to choose from and a size to fit nearly every operation.

Slurrystores can also help reduce odor, in some cases by up to 90 percent. Since the tank systems store manure above ground, a ‘chimney effect’ is created, releasing odors above ground level into higher-level air currents.

The company prides itself on providing customer support through its network of independent authorized dealers. Slurrystore also offers the customized ManurePro program, which can perform an analysis of a farm operation and provide the farmer information on how to save money using a Slurrystore system.

www.slurrystore.com

Octaform

|

Octaform Systems Incorporated produces a stay-in-place, concrete forming system that makes concrete walls stronger and offers more construction versatility for many of today’s demanding agriculture applications. With Octaform tanks, farmers are able to protect the environment and water quality through better storage, containment or processing.

With an Octaform tank:

• Stored liquids stay contained in the tank; there is no seepage into groundwater.

• Tank profiles are designed to produce a watertight wall when assembled and properly filled with vibrated concrete.

• The polyvinyl chloride (PVC) panels protect concrete and rebar from most chemicals.

• The concrete between the PVC panels provides excellent thermal mass, which delivers optimal temperature control with minimal fluctuation.

• Users receiver solid, long-life dependability, low maintenance and excellent sustainable containment compared to conventional construction.

• The smooth, flat, bacteria-resistant walls make cleaning effortless.

Octaform tanks are also rodent and insect safe. The solid, PVC-enclosed concrete walls prevent pests from entering. They also will not support combustion, making the system fire resistant.

www.octaform.com

LSC Pre-Cast Systems

Based in Pacific Canada, LSC supplies and installs a number of concrete-based products that help provide ecological solutions for the storage and maintenance of natural waste products that are used or produced through agriculture.

Specializing in pre-stressed concrete technology, LSC offers a variety of concrete span products to help resolve many of the issues faced by modern agriculture around the world. The company’s prefabricated, drop-and-go products – such as Rocket, ‘L’ and ‘T’ walls – provide rapid deployment solutions. Just drop them into place and go.

Tanks designed by LSC are practical yet cost-effective and can last for many years. The company is able to build to any height and hold any liquid, whether for waste management or a water reservoir. The panels are sealed using a non-toxic sealant.

www.lscprecast.com

Yunker Plastics Incorporated

|

Farmers committed to environmental responsibility and regulatory compliance have a simple solution when it comes to effective waste management and natural resource protection – the PondGard agricultural liner.

Whether lining an irrigation canal or a lateral, animal waste containment pond, a PondGard agricultural liner can provide numerous life cycle benefits while ensuring groundwater is protected. PondGard can be a cost effective solution. Liners require little or no regular maintenance following installation and can withstand normal environmental exposure for more than 30 years.

As an animal waste containment pond, the PondGard EPDM liner protects groundwater, lakes and rivers from contamination. PondGard’s elongation characteristics enable it to conform to objects in the sub-grade, including installation in areas with rock outcroppings or other challenging soil conditions. High tensile strength and ability to withstand temperature extremes ranging from minus 40 degrees F to 175 degrees F enables year-round installation.

PondGard agricultural liners resist puncture from difficult soil conditions including sand or rocky soil, and damage from large animal traffic. The liners meet the Natural Resources Conservation Service (NRCS) Conservation Practice Standard 541A and approved by NRCS for animal waste containment and other agricultural applications.

PondGard exhibits outstanding resistance to environmental conditions including ultraviolet (UV) radiation, ozone, weathering and thermal stress. PondGard is backed by a 20 year membrane weathering warranty.

www.yunkerplastics.com