A 1000 pound cow can produce as

much as 80 pounds of manure in one day. At that rate, a typical 1000

animal beef feed lot will produce up to 280 tons of manure in just one

week. That is a lot of manure and for the roughly 1800 U.S. feed lots

that have 1000 animals or more, it is an important management issue.

Most of the manure is collected and used as an organic fertilizer, but

some is lost due to runoff.

A low-cost, low-tech way to manage manure.

|

| The water on the left collected in a solids-separation basin at the low end of the feed lot pen (on the right) after a rain. After the solids settle, the water in the basin will be distributed throughout the vegetative treatment area.

Photo By Stephen Ausmus.

|

A 1000 pound cow can produce as much as 80 pounds of manure in one day. At that rate, a typical 1000 animal beef feed lot will produce up to 280 tons of manure in just one week. That is a lot of manure and for the roughly 1800 U.S. feed lots that have 1000 animals or more, it is an important management issue. Most of the manure is collected and used as an organic fertilizer, but some is lost due to runoff.

In the U.S., the main method for controlling runoff involves storing it in a large temporary pond or basin. Later, it is either distributed as nutrient-rich irrigation water or processed for safe disposal. Though approved by the U.S. Environmental Protection Agency (EPA), this method is far from perfect. Over time, the nutrients in the stored water can percolate through the soil, becoming a potential groundwater contaminant. Maintenance is expensive and difficult. The smell leaves much to be desired. And of course, as U.S. Department of Agriculture (USDA) Agriculture Research Service (ARS) research leader John Nienaber points out, “Nobody really wants to look at a manure storage pond.”

In the Environmental Management Research Unit at the U.S. Meat Animal Research Center (USMARC) at Clay Center, Nebraska, agricultural engineers Roger Eigenberg and Bryan Woodbury have joined Nienaber in developing and testing an alternative method of runoff control that avoids many of the disadvantages of traditional runoff control systems.

|

| Technician, Todd Boman collects soil electrical conductivity readings as he drives through the field. These values are used to generate maps illustrating nutrient distribution in the vegetative treatment area.

Photo By Stephen Ausmus.

|

Under the alternative system, runoff containing manure solids enters a small temporary storage basin at the base of the feed lot. The basin is large enough to hold runoff for several minutes to allow the solid waste to collect on the bottom. The remaining liquid is then drained through distribution tubes, providing

even dispersal over a vegetative treatment area, or VTA, which is essentially a grassy field. Distribution of the liquid is controlled so that a full basin would empty in six to eight hours, though the process begins as soon as the liquid separates from the solids in the basin. In the fall, solids are removed from the basin and used as fertilizer on adjacent cropland.

The Clay Center VTAs are about twice as large as the surface area of the feed lot pens, a size that efficiently uses runoff water and manure nutrients. The technology could also be applied to other livestock – in fact, the team will soon begin collecting data from a sheep feed lot VTA – but managers would have to adjust basin and field sizes accordingly.

The VTA system, which has been conditionally approved by EPA, has many benefits. It requires minimal management, significantly reduces waste storage time and eliminates the need for costly pumping of runoff through distribution equipment. In addition, it removes standing water, which can promote the growth of bad-smelling compounds.

This system should be less expensive to construct and maintain than the traditional system, the scientists say, though the cost and suitability would vary with geography, climate and animal type. “Our objective was to design runoff control systems that require minimal operator input and use standard equipment to manage,” Woodbury says. “These systems can incorporate more sophistication, but each level adds costs and management time to ensure proper operation.”

|

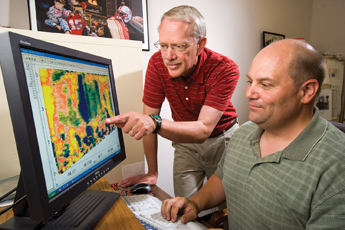

| Agricultural engineers, Roger Eigenberg (left) and Bryan Woodbury evaluate a soil electrical conductivity map to estimate field nutrient levels and salinity in a vegetative treatment area.

Photo By Stephen Ausmus.

|

For the VTA system to catch on, the scientists need to prove that their method is better than traditional containment. After eight years of operating tests, they are confident that the technology is environmentally sustainable. The scientists use the liquid discharge – which contains nitrogen – to grow hay in the VTA. They found that after harvest, the amount of nitrogen contained in the hay equaled or exceeded the amount they estimated would have entered the area through liquid runoff. Over a four year period, the scientists found no evidence of water leaching from the VTA, suggesting that the alternative system’s potential for contamination is lower than that of traditional management.

Eigenberg and Woodbury are making full use of technology to evaluate and compare the environmental impacts of the new and old runoff-control systems. They have been using electrical conductivity maps and soil samples to estimate the levels of nutrients and salts in the field. To improve this analysis, they are incorporating a salinity assessment package called ESAP – short for Electrical conductivity or salinity, Sampling, Assessment and Prediction – into their mapping program. The program was developed by ARS scientists based at Riverside, California and helps determine the best places to take soil samples. It estimates the amount of nutrients, such as nitrogen and phosphorus, in the soil.

|

| Runoff from a feed lot pen during a rain event. The water is heavily laden with sediment from the pen surface.

Photo Courtesy Of USMARC.

|

Eigenberg and Woodbury collect GPS co-ordinates and soil electrical conductivity measurements and use that information to develop two-dimensional maps. “When comparing the maps over time, we can observe changes in soil

salt concentrations by measuring the changes in soil electrical conductivity,” says Eigenberg. “Increases in salt concentrations tell us where the runoff is going. All this information provides us with a tool to better manage the runoff-control system.” For example, with their maps, the scientists have found areas in the VTA that were receiving too much runoff and have been able to direct the runoff to areas that were not receiving enough.

In January 2006, USMARC became the first site in Nebraska to receive EPA approval to construct a full-scale system using the new technology. The scientists have since built three new systems and redesigned the original test model. All four systems are similarly constructed, though two have larger solids-separation basins – designed to hold more runoff – and a different pipe arrangement for liquid distribution. In future studies, the researchers will compare the influence of basin size on a system’s ability to separate solids when runoff pressure is higher, for example, during a heavy storm.

“Everyone stands to benefit from this VTA technology,” says Nienaber. “There are lower maintenance costs for the producer and improved environmental protection for consumers and local residents. Plus, nobody has to look at the unsightly mess of a storage pond.”

Laura McGinnis is with the USDA’s Agricultural Research Service Information staff.