Features

Applications

Beef

Environment

Research

Analyzing feedyard emissions in the Texas Panhandle

August 6, 2018 by Kay Ledbetter

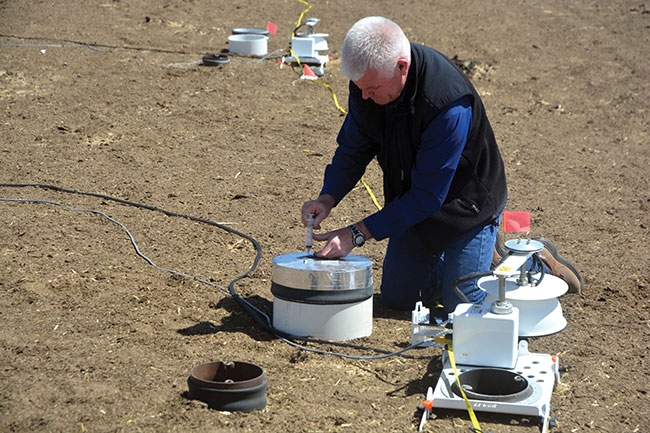

Dr. Ken Casey, Texas A&M AgriLife Research air quality engineer in Amarillo, collects a greenhouse gas sample from a static flux chamber. Texas A&M AgriLife photo by Kay Ledbetter

Dr. Ken Casey, Texas A&M AgriLife Research air quality engineer in Amarillo, collects a greenhouse gas sample from a static flux chamber. Texas A&M AgriLife photo by Kay LedbetterA week spent in a feedyard pen is helping researchers gain a better understanding of greenhouse gas emissions. Their goal is to improve the national inventory of greenhouse gases and determine potential mitigation measures.

Texas A&M AgriLife Research and the U.S. Department of Agriculture-Agricultural Research Service are collaborating to analyze nitrous oxide and methane emissions from an area feedyard pen.

Dr. Ken Casey, AgriLife Research air quality engineer in Amarillo, and Drs. David Parker and Heidi Waldrip, USDA-ARS livestock nutrient management researchers at Bushland, spent the better part of a week sitting inside a vacated feedyard pen.

The project is funded by USDA-ARS and AgriLife Research with support from the Texas Cattle Feeders Association.

Using six automated chambers, more than 575 automated flux measurements were taken, as were 60 manual flux measurements from separate static chambers, to help monitor nitrous oxide and methane gas emissions. Halfway through the experiment, a half-inch of water was applied to the pen surface within the measurement chamber bases to simulate a rainfall.

“We’re looking to understand better what controls nitrous oxide and methane coming off feedlot pen surfaces,” Dr. Casey said. “We’re interested in the emissions of these gases because of their contribution to climate change. We want to improve the national emissions inventories as they pertain to greenhouse gases from feedyards in the Texas High Plains.

“Secondly, we are also very interested in obtaining a better mechanistic understanding of the evolution of these gases from the pen surfaces. What controls the release of these gases? If we are able to gain a better understanding of that, then we will potentially be able to provide advice to the industry about mitigation practices when it comes to pen management.”

Dr. Casey said their testing demonstrated areas of the pen with shallower manure packs on the surface primarily emitted nitrous oxide, while two chambers sitting over deeper manure where the pen drain was located emitted almost no nitrous oxide, but were emitting methane.

“We are trying to understand the interplay of those two gases, because the processes that are producing them are related,” he said.

The different factors that influence the creation and release of the gases include temperature, moisture content and the amount of manure on the pen surface, Dr. Casey said.

“By understanding how those factors play together in the production of those gases, we can develop a greater understanding and potentially develop mitigation strategies,” he said. “However, it’s complicated, because a strategy that reduces one emission may in fact increase the other.”

During the study, gas samples were collected twice a day from the static chambers and taken to Dr. Casey’s air quality lab to be analyzed. Six automated chambers took measurements each hour, around the clock. The automated chambers were linked to automated nitrous oxide and methane analyzers.

“We know emissions are influenced by temperature, and by taking diurnal measurements, we can understand the variability throughout the day and night, as well as that of the effects of moisture.”

The week of measurements is only part of ongoing research being conducted by Dr. Casey and Dr. Parker. Dr. Casey said the results will be reported to the industry, as well as in various journals, and will be used for extended air quality research.

Their research is also relevant to manure quality.

“Not only is this research important for greenhouse gas emissions, but through this and ongoing laboratory studies, we are learning more about nutrient transformations and water losses from the feedyard surface,” Dr. Parker said.