Features

Applications

Other

Ammonia emissions from confined feeding operations (CFOs): control and mitigation

July 10, 2008 by Dr. Atta Atia*

This article is intended to

provide producers and farm managers with information on how to reduce

ammonia emissions from livestock housing and manure storage facilities.

By reducing ammonia emissions, producers can maintain the quality of

the environment, prevent losses of significant portions of nutrients

and improve the health and safety of animals and workers.

This article is intended to provide producers and farm managers with information on how to reduce ammonia emissions from livestock housing and manure storage facilities. By reducing ammonia emissions, producers can maintain the quality of the environment, prevent losses of significant portions of nutrients and improve the health and safety of animals and workers.

Although there is no direct relationship between ammonia emissions and odor, practises to reduce ammonia emissions can have a corresponding mitigating effect on odor generation.

| Within agricultural activities, ammonia emissions into the atmosphere occur primarily from livestock buildings, open feedlots, manure storage facilities, during manure handling and treatment, and when manure is applied on land. |

Sources of ammonia

Agricultural activities (livestock production and fertilizer application) are identified as the major sources of atmospheric ammonia emissions in Alberta, followed by biomass burning. Within agricultural activities, ammonia emissions into the atmosphere occur primarily from livestock buildings, open feedlots, manure storage facilities, during manure handling and treatment, and when manure is applied on land.

Ammonia in livestock facilities results primarily from the breakdown of urea by the enzyme urease. In most livestock, urea is only present in the urine while urease is present in the feces. In poultry, urease is excreted with uric acid in the feces.

Why control ammonia emissions?

Ammonia emissions decrease the nutrient value of manure and represent a significant loss of fertilizer value. The emissions have a negative effect on the environment such as soil acidification and eutrophication of surface water (water is nutrient-rich, supporting plant life that kills animal life by depriving it of oxygen).

Ammonia that is lost to the atmosphere combines with nitric acid

to form aerosol nitrate, which contributes significantly to total particulate matter. These particles have serious effects on human health and cause air quality impairment.

Ammonia poses a threat to both animals and agricultural workers in livestock facilities. It is a significant respiratory hazard for workers who experience continuous, long-term exposure to the gas at concentrations greater than 25 parts per million (ppm). In addition to respiratory effects, ammonia can cause skin and eye irritation and displace oxygen in the bloodstream. Long-term exposure to ammonia can cause pneumonia.

| Trees, shrubs and other vegetative barriers planted around livestock buildings have the potential to reduce ammonia emissions as they act as a type of biofilter for odorous compounds attached to fine dust particles. |

| Using ventilation techniques that create low air velocities around surfaces exposed to manure can help reduce ammonia emissions. |

Ammonia control technologies and best management practises

Ammonia is emitted from manure in livestock buildings, manure storage facilities and during manure application to soils; therefore, several technologies or beneficial management practises (BMPs) are needed to control ammonia emitted from the various sources or CFOs. A whole spectrum of suppressive, inhibitive, capture-and-control technologies and BMPs are available for the elimination and/or reduction of ammonia emissions from livestock operations.

To-date, no technology or BMP emerges as a clear choice for industry to use to mitigate ammonia emissions due, in part, to the associated cost (real and perceived) of implementation and the required long-term implementation of the technology or BMP. A technology that can completely prevent ammonia emissions or remove ammonia from the air either does not yet exist or is prohibitively expensive to install and/or manage.

The effectiveness of a particular technology or BMP depends on three factors: efficiency, applicability and cost. Producers are advised to implement efficient but less costly technologies or BMPs or combinations of both. Producers should seek the advice of appropriate professionals and experts regarding ammonia emissions mitigation and control techniques that suit the needs of their livestock operations.

Suppression methods

Impermeable covers – Rigid, impermeable covers include concrete or wood lids placed on the top of liquid storage units and lightweight roofs made of fiberglass. Rigid covers are usually more expensive than other types of covers, but often last longer, 10 to 15 years depending on the material, according to Dr. Jose Bicudo – former assistant extension professor in the Department of Biosystems and Agricultural Engineering at the University of Kentucky – and others. Impermeable covers are capable of reducing 80 to 95 percent ammonia emissions from manure storage facilities.

Permeable covers – Permeable covers, or biocovers, act as biofilters on the top of manure storage areas. They physically limit the emissions of ammonia and other gases from the surface of storage lagoons and create a biologically active zone where the emitted ammonia and other gases will be aerobically decomposed by micro-organisms.

Permeable covers and biocovers include chopped barley, wheat, oats or brome straw (eight to 12 inches thick). The effectiveness of ammonia emissions control is lower than with impermeable covers. Permeable covers are cost effective, but they require replacement over time, and they are vulnerable to extreme weather conditions.

For more information on permeable and impermeable manure storage covers, refer to Covers for Manure Storage Units, Factsheet 925-D (website http://agbiopubs.sdstate.edu/articles/FS925-D.pdf ).

Acidification – Research in Europe has proven that acidification of manure just before application reduced ammonia volatilization depending on the degree of acidification and the application technique. Because acidification is a suppression technique, the potential exists for ammonia to be volatilized in downstream processes (e.g., storage or land application) if the pH increases above 4.5.

Furthermore, using acidifying agents to suppress the ammonia emissions from manure may favor conditions for the release of more hydrogen sulfide into the environment. Finally, the cost of chemical additives varies widely and can be cost-prohibitive for smaller operations.

Inhibition methods

Manure management in barns

Ammonia emissions from a liquid manure surface are proportional to the surface area of the manure. Therefore, decreasing manure surface area by changing the shape and dimensions of a manure storage facility will reduce ammonia emissions from the barn.

The type of floor area exposed to manure in animal housing facilities can have a significant effect on the emissions rate of ammonia. Emissions of ammonia from the solid part of the floor can be reduced by using a smoothly finished inclined or convex surface.

Decreasing the length of time manure remains in a livestock building is an important factor in reducing ammonia emissions, which can be achieved by the frequent removal of manure from livestock buildings or pens and the daily flushing of manure from barn alleys.

Using ventilation techniques that create low air velocities around surfaces exposed to manure will also help reduce ammonia emissions. Air speeds across manure-covered surfaces should be minimized since the amount of ammonia gas given off by manure is increased with air speed. Keeping buildings and animals clean and dry is essential for reducing ammonia emissions.

Separating manure from urine may slow the rate of reaction that leads to ammonia generation and may help minimize ammonia volatilization. Most systems employ a separator or a belt conveyor whereby feces containing urease are captured on the belt and urine is stored below. As much as 80 percent reduction in ammonia emissions is expected using this system but the practise has not yet been implemented commercially. According to an Iowa State University extension publication, Practises to reduce Ammonia Emissions from Livestock Operations, several urine/feces segregation systems are under development at this time.

Manure pH has an important effect on the ammonia release. A lower pH value results in less ammonia being emitted. As pH increases above 7.0, the concentration of ammonia increases as does the rate of ammonia volatilization. The pH of manures handled as solids can be in the range of 7.5 to 8.5, which results in rapid ammonia volatilization. Manure handled as liquids or semi-solids tends to have lower pH. According to Dr. T.T. Lim from the University of Singapore, and others, adding a layer of water to the bottom of manure pits prior to manure collection helps reduce initial ammonia emissions from the pits.

Diet manipulation

Nitrogen fed in excess of the requirements of livestock animals is not retained by the animal’s body but is simply passed out in the urine and feces. Matching feed to the nutritional requirements of animals reduces nitrogen excretion without affecting productivity. Production can be significantly affected if protein levels are reduced excessively.

Research found that ammonia emissions could be reduced in dairy cows by up to 20 to 30 percent by manipulating dietary crude protein types and levels. Feeding a reduced crude protein amino acid-supplemented diet is also an effective tool for reducing ammonia emissions from growing-finishing swine housing.

Phase feeding is a commonly used practise for meeting livestock nutrient needs without exceeding them. No cost information for diet manipulation was found in a literature review; however, dietary manipulation has the potential to reduce feed costs. Producers should consult with extension personnel or certified livestock nutritionists for more information on diet manipulation.

Capture-and-control methods

Filtration and biofilteration

Biofilters are usually comprised of ventilation fans that exhaust air from buildings through ducts and into a plenum below the biofilter media. The air passes through the biofilter media where micro-organisms treat it before it is emitted into the atmosphere.

Although biofilters have the potential to effectively reduce substances in the air, such as ammonia, implementation of this technology is not guaranteed to be effective in every application. Several factors determine the effectiveness of biofilters and their practicality. Experiences with pig farms in Alberta indicate that these filters can be costly to install, operate and maintain. In addition, biofilters require close, frequent monitoring and intensive management to ensure optimum operational conditions are achieved continuously.

Bioscrubbing and ammonia stripping

The concept of bioscrubbing is similar to biofiltration. Both methods rely on the microbial degradation of ammonia. The difference between bioscrubbing and biofiltration is that the bioscrubber is housed in a closed tower containing water. When ammonia passes through the tower, it will be captured and absorbed by the water and then oxidized by the micro-organisms. A high reduction of ammonia emissions by scrubbing has been reported in numerous research publications. However, the cost and applicability to Alberta situations have not been established.

Ammonia stripping is a process for removing ammonia from manure. Air stripping in combination with absorption can be used to remove and recover ammonia from manure. Ammonia is transferred from the manure stream into the air and then absorbed from the air into a strong acid solution (typically sulfuric acid), thereby generating an ammonium-salt, which can be crystallized and used as fertilizer. Values of pH from 10.5 to 11.8 are generally considered to be required for effective ammonia stripping processes.

Landscaping

Trees, shrubs and other vegetative barriers planted around livestock buildings have the potential to reduce ammonia emissions. Trees and shrubs act as a type of biofilter for odorous compounds attached to fine dust particles. They also offer visual protection for livestock buildings.

A demonstration site on the Delmarva Peninsula has shown up to a 67 percent reduction in ammonia levels downwind of vegetative filter belts planted on commercial broiler farms.

Summary

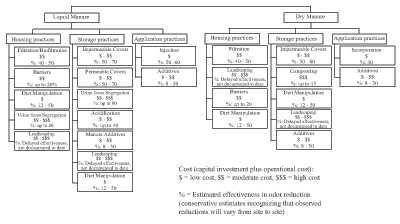

Practises to control ammonia emissions associated with livestock can be applied to animal housing areas, manure storage areas and land where manure is applied (see Figure 1).

|

| Figure 1. Practises to reduce ammonia emissions from livestock operations flowchart. Reproduced With The Permission Of Iowa State University, University Extension. |

*Dr. Atta Atia is a livestock air quality specialist with Alberta Agriculture and Rural Development (AARD). This article is taken from a fact sheet produced by AARD, Ammonia Emissions from Confined Feeding Operations (CFOs): Control and Mitigation, Agdex 729-4)